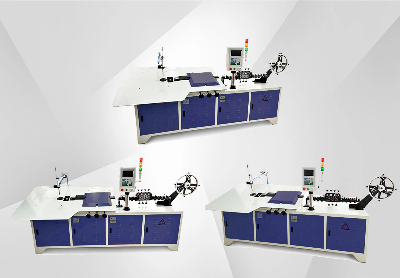

Forming Wire Bending Machine Technical Parameter:Project /

ModelRN-06-6AMachining line diameter3.0mm - 6.0mm soft steel wire

(20# steel)Maximum wire feeding speed50m/minThe minimum time

required to twist the head 90 degrees0.1sThe minimum time required

to reverse the transformation of the core0.2s The minimum

time required to turn the line at 90 degrees0.2sMaximum lifting

speed of torsion mechanism250mm/sec Maximum feed

strokeUnlimitedFeeding modeRoller feed lineMaximum bending

radius20mmMaximum bending angle180°Every set bending

numberUnlimitedSet number of filesUnlimitedWorking speedBending

speed180°/0.5secRotation speed360°/2secFeed

speed700mm/1secAccuracyBending angle±0.05°Angle of

rotation±0.05°Material input mode1.numerical formula; 2. teaching

methodControllerIndustrial computerCNC data inputTouch screen input

+ hand wheel inputBending (C) servo motor power1.0 KWRotating (B)

servo motor power1.0 KWPower supply (Y) servomotor

power2.0KWElectrical capacity15KVAMachine weight2000KGMachine size

L*W*H(mm)2300*1600*1650MMCompany InformationRonen Group is

committed to designing and manufacturing of induction heating

equipment, which are widely used in machinery,building materials,

metallurgy, papermaking, automobile manufacturing and other fields,

to fully meet the needs of steel pipe seam welding, stainless steel

pipe welding, strip heating, vacuum melting, copper pipe Welding,

steel pipe annealing,refrigerator tube welding, metal heat

treatment, metal smelting, welding, brazing, thermal assembly and

other induction heating process requirements, mainly include spring

steel wires, high-strength pipe piles PC steel rods / PC bar,

Prestressed steel wire,Prestressed Concrete strand, rebar,

aluminum-plastic pipes, wires and cables production equipment

lines.Ronen Group domestic market share is more than 60%, and

In recent years, we have exported our machines to USA, Europe,

Russia, Egypt, Japan, Korea etc. more than 25

countries.Ronen will always be here for you!Metal Wire Forming

Bending Machine DescriptionAutomatic Hydraulic Metal Twisted Round

Ring 3D Wire Bending MachineAmerican Market Quality Auto 3D CNC

Wire Bender /Automatic 3D CNC Wire Forming Machine Metal Bending

Machine/Steel Bar Bending MachineSteel Wire Bending Machine Product

Advantages:1. In principle, the head turning molding machine has

the advantages of no turning, light head structure and no turning,

which ensures the fast and stable production operation.2.

Computer power on, power off fast, simple and convenient operation.

The computer interface can adjust the speed and change the program

at the same time of production.3. High speed motor imported

from Japan and reducer imported from Germany are used in the

configuration. The production speed is more than 25% higher than

that of domestic counterparts.4. Wire feeding and rotating arm

are separated and matched. When the head is turned, the wire can

not be turned, and the small outer diameter arc and multi

circle products can be formed.5. The production can realize

that the angle does not change at the slowest angle, and the

production stability is better.6. Bearing, gear and other important

parts are imported from Taiwan, with 8760 hours guarantee, and the

equipment is durable and reliable.7. High precision, can do 2.0-14

mm wire diameter range of wire forming products, error reduced to

0.1 mm8. The matching use of the steel wire butt joint machine

makes the line changing operation of the machine more

convenient.Ronen Group Related Products Ronen Group Exhibition

InformationCertificationsFAQ1.Q:Are you manufacturer?

A:Yes, We are manufacturer.2.Q: What are the payment

terms? A: Pattern of pattern :we can accept L/C ,T/T ,

Western Union , Money Gram 3. Q: What is the whole business flow

cooperation with us ? A:1.Firstly,send your inquiry

to us,make us have learned your requirement

2.We will be drawing a proforma invoice according to your

requirement ,and start production after you finished to pay

30% deposit.

3.All of the goods, packing details, and B/L copy will be

send to buyer after finished production. We will arrange

shipment and provide original B/L

after the buyer finished to pay the balance. 4. Q: What if you

encounter technical problems? A:Please contact

us as soon as possible and let us know what kind of technical

problems you encounter and the details.

We will give you a solution within 24 hours. 5. Q: What advantages

we have? A: Rich experience: We have been in this

line for 20 years . we can provide solution according to the

problem of the buyer meet in the production

process./* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about CNC Statinless Steel Metal Solid Bar Bathroom Furniture Seat Snake Cushion Hooks Metal Twisted Round Ring CNC 2D 3D Wire Bending Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup