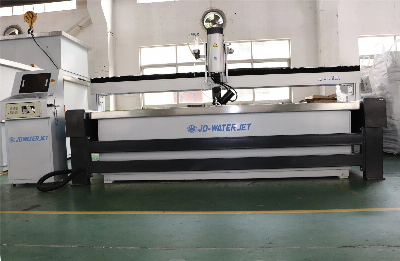

Water jet cutting machine, for precise cutting of

metal,stone,wood, rubble material with 3 axis or 5 axis

high pressure Abrasive CNC Waterjet Cutter Machine with

Intensifier PumpAs one of the main cutting process, water jet

cutting machine is getting more and more popular with laser

cutting and plasma cutting . Please read the

following introduction of our product and contact us

for any question! BenefitsPrecisionCutting at very high

pressure allows precision of the order of a tenth of a millimeter

without damaging the mechanical properties of the materials cut (no

heating or deformation). SimplicityThe controls and functions

for using the machine are simple and intuitive.Adjustment

operations are very easy and cutting starts in a few

clicks. VersatilityOur machines allow custom cutting of

complex shapes, in all materials, regardless of size and without

having to change tools.Product IntroductionJD water jet Cutting

Machine WJ50-3A-3020BAWater jet is kind of using high pressure

water cutting machine, belong to the category of could cutting, has

the advantage such as compact structure, no spark and not produce

thermal deformation or heat effect. A high pressure water jet

cutting machine is a tool used for slicing metal and other

materials using a jet of water at high velocity and pressure.

Featuring a low noise, no pollution, high precision and high

reliability, our water jet cutting machine has been used in

a variety of applications, including mining, automobile

manufacturing, paper manufacturing, food, art and

architecture.Structural styleBridge style X and Y axis

Travel3000mm×2000mmZ-axis Travel150mmControl accuracy±0.01mmCutting

accuracy±0.2mmServo motor specification0.75KWX/Y-axis Max. moving

speed6000mm/minZ-axis Max. moving speed1000mm/minProduct

AdvantagesJD-3020BA 3 axis waterjet cutting machineA high

pressure water jet cutting machine is a tool which slices into

metal and other materials, using a jet of water at high

velocity and pressure. Because of its advantages of low noise, no

pollution, high precision and good reliability, it has been widely

used in mining, automobile, paper-making, food, art, construction

and other industries.Water jet can cut almost every thing,

including metal, glass,plexi glass,ceramic,marble, granite,

rubber and compound material etc. Cutting accuracy:+/-

0.1mm Repeat accuracy:+/- 0.05mmTechnical

InformationJunda Water Jet Cutting Machine All ModelsApplicationA

high pressure water jet cutting machine is a tool used for

slicing metal and other materials using a jet of water at high

velocity and pressure. Featuring a low noise, no pollution,

high precision and high reliability, our water jet cutting machine

has been used in a variety of applications, including mining,

automobile manufacturing, paper manufacturing, food, art and

architecture.Cutting samplesDesigned & manufactured to

perfection, we are one of the well known and leading manufacturers

and exporters of Water Jet Cutting Machinery. At our premises, we

are manufacturing the cutting machinery utilizing premium quality

of raw materials and components. In addition to this, the cutting

machinery is best known in the market due to its remarkable

features such as high performance, easy operation and durability.

This Machinery finds usage in many application such as automotive,

aerospace and electronics for cutting metals and non metals.

Transportation & PackagingInstallation And After-sales

ServiceCompany IntroductionJINAN JUNDA INDUSTRIAL TECHNOLOGY was

established in 2005. We are the professional manufacture and

exporter for garnet sand, steel shot, steel girt, bearing steel

grit, , glass beads and other surface treatment abrasives.About the

garnet sand, we integrate mining, production and sales, we have

adequate reserves. In recent years, our garnet sand production

capacity raise from thousands of tons to ten thousands. We set the

good reputation in garnet industry all over the world.About the

steel shot, steel grit and bearing steel grit, our product reach

American SAE standard, they are widely used in shipbuilding,

moiding, steel, and automobile, container, machinofacture, pipeline

anti-corrosion, aviation, granite cutting and so on.Abour the glass

beads, We can product different road marking glass beads,

sandblasting glass beads, and grinding glass based on different

requirements of customers and according to the standard: EN1423 and

EN1424; American Standard: AASHTO M247 type 1 and type 2; British

Standard: BS6088 Class A and B; Japanese standard: JIS R3301; Korea

Standard: KSL 2521 No. 1 and 2;Our philosophy is to build growth on

a foundation of high quality, provide excellent service to our

customers. We product strictly according the ISO quality standard.

And in-depth application knowledge. Highly efficient logistics are

central to the company′s culture, and JINAN JUNDA INDUSTRIAL

control of matarials strictly from source to use, that ensure

ensure quality and consistency. Our product sale to USA,

Related products about Junda Waterjet Cutter Machine Stone Metal Cutting High Pressure CNC

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup