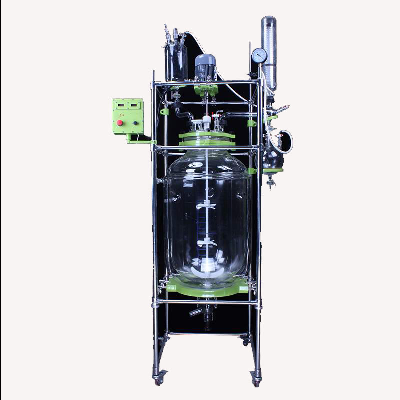

Easy Operate Double Deck Esterification Reactor with

Iso9001 Product Description Easy Operate Double Deck

Esterification Reactor with Iso9001Lanphan S212-150L double-layer

glass reactor's reaction flask volume is 150L, interlayer volume is

23L, stirring diameter of axle is 15mm, power of stirring is 750W.

S212-150L double-layer glass reactor is an audacious product who

has combined advantages of domestic and foreign like products, it

adopts double-layer glass design, put reaction solvent in internal

layer to do stirring reaction, connect different cold and heat

sources(refrigerating fluid, hot water or hot oil) to interlayer to

do cyclic heating or cooling reaction. Under set constant

temperature condition, you can conduct stirring reaction under

normal or negative pressure in airtight glass reactor, as well as

conducting backflow and distillation of reaction solution.

S212-150L double-layer glass reactor is an ideal pilot test and

production equipment for modern fine chemical engineering,

biological pharmacy and new material synthesis. This glass reactor

series mainly contains following parts: double-layer glass reaction

kettle, a set of component cover of glass reactor, condenser,

constant voltage funnel, frequency conversion controller, rotate

stirring and sealing system, stainless steel frame system,

etc. Product features of S212-150L double-layer glass

reactor:Constant rotate speed, no electric brush, no spark, safe

and stable, enable continuous working.Full set of glass part is

produced by G3.3 borosilicate glass, owns excellent chemical and

physical properties.When glass interlayer connecting to hot oil and

been circulated, it can do heating reaction, connecting to

refrigerating fluid can do low temperature reaction.Enable reaction

under normal temperature, that is connecting to tap water can take

away the reaction heat quickly.Discharge outlet has flange mouth

and PTFE valve, there has no dead angle in vessel, detachable and

convenient for solid material to discharge.Main body is made from

stainless steel, which is beautiful and anti-corrosion.Sealed by

PTFE component, be able to maintain higher vacuum degree.Be able to

work under normal and negative pressure, negative pressure up to

-0.09MPa.Alternating current dynamo conducts frequency control

stirring, reliable operation, large moment of force and no

spark.The inner core of stirring rod is made from 321 stainless

steel, strengthened anti-corrosion property, military technology

makes workmanship more exquisite, operation with high

proficiency.Spectifications Specifications of Easy Operate

Double Deck Esterification Reactor with Iso9001Basic

ParameterTypeS212-150LGlass materialGG-17Frame materialStainless

SteelPipe fitting material304 Stainless SteelMove methodUniversal

castors with brakingReaction flask volume150LInterlayer

volume23LFlange type oil in and out circulation portEnter from low

port, come out from high portNumber of reactor bottle6Discharge

outlet liftoff height450mmReactor reaction temperature-80-250

degreeVacuum degree0.098MpaStirring speed0-280rpmStirring diameter

of axis15mmStirring

power750W1/5Voltage/Frequency(V/Hz)220V/50HzBoundary

dimension(mm*mm*mm)1250*850*2920Package weight(KG)160Functional

ConfigurationsSpeed adjustment modeElectric stepless speed

regulationElectrical machine configurationLow speed reinforcement

electrical machine, speed ratio 5:1Rotate speed display modedigital

displayTemperature display modePT100 sensor digital displaySealing

modePTFE sealing, ¢60 flange stirring

mouthCondenser Vertical high efficiency double backflow

condenser pipe 120*800mmBackflow (distillation)

device Backflow elbow is equipped with discharge switch, 50#

ball milling mouthReceiving device10L receiving bottleDropwise

adding device2L dropwise bottleDepression device 34# standard

mouth reducing valveTemperature testing tube24# standard mouthSolid

charging¢80 flange mouth with PTFE coverDischarging

methodInclined glass discharging valve, ¢80 flange mouthVacuum

display modeVacuum meterStirring connecting methodUniversal joint

connectingStirring barAnchor type stainless steel bar, covered with

PTFEOur company's laboratory glass and laboratory instruments are

independent research and development, available for custom-made

according to client requirements.Packing List of Easy Operate

Double Deck Esterification Reactor with Iso9001Serial

NumberAccessory NameQuantityExplanation1Double-layer reactor1

pcEffective volume 150L2Stirring electrical machine1 pcRotate speed

starting -1350 rotate(adjustable)3Speed controller1 pcWith digital

display function(stepless speed regulation)45 mouth reactor cover1

pcMatching use with reactor5Reactor shelf1 setTo support

rector6Condenser1 pcDistill and condensate7PTFE discharging device1

pcDischarging(detachable)8Thermometer well1 pcTo put

thermometer9Constant Voltage funnel1 pcCharging in vacuum

condition10PTFE stirring bar1 setInner diameter is made from

stainless steel material, covering is made from PTF

Related products about Temperature Hydrogenation Glass High Pressure Chemical Reactor for Ethylene Polymerization

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup