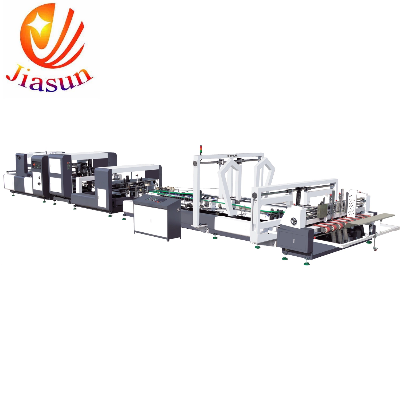

Specification: Specifications & Carton Size

Comparison TableModelJHXDX-2600Installation

Area16000*3500mmTotal Power23KwSheet ThicknessA, B, C, ABPitch

Range40-500mmNail Number1-40(nail)Wire SizeNO.17(2.0*0.7mm),

NO.18(1.81*0.71mm)Nail length38mm(can be customized)When do

gluingModelJHXDX-2600 Max(mm)Min(mm)A680200B570100C680200D570100E2500780F1000300G35-40When

do

stitchingModelJHXDX-2600 Max(mm)Min(mm)A600240B650200C600240D650200E2500880F1000350G35-40Features

Of the Machine: Key

FeaturesUnique separate sheet separation and registration part which can eliminate the fish tail phenomenon effectively.Gluing, stitching, glue + stitching can be set through one button press which is very convenient for the operation The stitcher cutting knife and nail stand adopts imported hard alloy which ensures long working life span

Order saving function can store the carton size in touch screen,

machine will adjust automatically when the operator selected an

saved order.Main FeaturesPatent design of 90°angle folding knife

can make the carton folding precisely. The imported Yaskawa brand

of four-servo motors with accurate features, it can reduce the

transmission devices and makes trouble free.Using motor to adjust

the synchronous belts, easy operation and reduce change time.Swing

style stitching head, synchronous belts and stitching head moving

synchronously, it can achieve stitching while sheet moving, fast

speed and high efficiency.Features by Parts: Feeding

Unit: Adopt

high quality rubber vacuum belt, stocking and automatic input to

ensure the efficiency of feeding. Special design makes the

adjustment simply, quickly and precisely. Pneumatic side

regulation, paper feed baffle and belt are separately operated,

which make the order change easy.Gluing Unit: The gluing

width is 25mm/35 mm-gluing from bottom side. The glue box can be

moved left or right according to the requirement of the corrugated

board. The gluing amount can be adjusted.The glue box is made of

stainless steel-big contain and easy for cleaning.e) The

electrical control system makes nail stitching more precise.f)

Automatic nail feeding device, four sensors detecting the

nail shortage break. Folding Unit It uses high friction

belt. The folding speed is controlled by frequency converter which

can be controlled separately and synchronized with the main

motor.Motor driven for order change adjustment-fast and

convenient.Re-creasing roller, re-creasing knife, side roller and

flapping plate can eliminate the fish tail effectively. The

re-creasing knife adopts new design and structure which makes the

carton folding straight and perfect.The top strengthen parts adopt

liner slide rail and pneumatic lock device, it makes the machine

running stably in high speed which can ensure the folding

precisely. Sheet Separation and Registration Unit

Our unique design of sheet side lay and speed disparity unit can

connect with other automatic folder gluer.When choose stitching

mode, there has two servo motors control the sheet aligning

actions, secondary compensation and correction system eliminates

fish tails phenomenon. Automatic Adjusting FunctionRe-design

and structure of support wheels, electric control and motor driving

make the adjustment fast and convenient, suit for different

thickness corrugated board.Take the top part of corrugated sheet as

the base line getting an accurate positioning and reducing the fish

tail problem greatly.Motor and encoder make the adjustment easy and

convenient, the operator can save the sheet data though touch

screen. Stitching Unit Adopts Synchronous belt drive,

PLC control system, touch screen adjustment, convenient, fast and

accurate.The swing style stitching head with the features of less

power consumption, faster speed and high stability can effectively

enhance the product quality.One button control the gluing mode and

stitching mode exchange, all adjustment controlled by electric

motor.The nail pitch and stitching head up and down are controlled

by electric motors. The cut-off knife adopts cemented carbide

material, long service life.The nail shape can be adjusted as sheet

requirement. Stacking and Counting UnitThe Flapping Plate can

help to reduce the fish tail phenomenon when gluing.The pile

number can be set at 10, 15, 20 and 25. Electrical PartsScientific

and reasonable mechanical structure, reliable quality electrical

elements makes the machine free of trouble. Yaskawa brand servo

motor can ensures the life span.Working ProcessesAuto feeding

Auto

gluing/stitching Auto

folding

(1)Manual

bundlingAuto stacking and counting

(2)Auto

bundling Installation

Requirement Installation areas:Length × Width :

16000×3500mmTraining, installation and debuggingSeller in charge of

installation, debugging and training in the buyer's factory.

However the days used should be generally no more than

seven daysThe buyer should try to help as much

Related products about High Speed Automatic Corrugated Carton Box Paste and Nail Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup