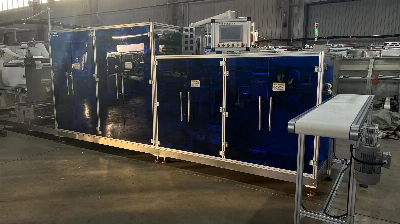

YY-DP-400 Portable Single Piece High Speed Wet Wipe Making Machine

For Travel Restaurant (1) Technical

parameters: Product

TypeDisinfectant Wipes , Cosmetic Wipes , and Cleansing WipesDesign

speed450 pieces/minuteProduction speed250-400

pieces/minute (depending on the material)Number of pieces per

pack1 piece/packApplicable materialsspunlace non woven, degradable

materialsMaterial weight35 -80 grams/m2Packaging film

thickness0.025mm -0.065mmWorking voltage380V 50HZPower10KWRaw

material roll width150-300mmUnfolded size (mm)( 160-260)

x ( 150-300) ( L x W)Folded size (mm)(80- 130)

x (50-85) ( L x W)Packaging filmPE & PET, OPP & PE

(aluminized film), OPP & CPP, PE T& CPP (aluminized film)Packing

bag size (mm)( 100-200) x (60-80) (L

x W)Folding way"Z", "W"Humidification systemMixing bucket

with agitator, spray, soaking mode can be switchedLiquid storage

tank400LMachine size (mm)6000× 1100× 1700(L×W×H)Tank size

(mm)800x 900 x 1500Machine weight2500kg(2) Main features:1.

Scientific design, compact structure, easy operation and

maintenance.2. The main mechanical parts are made by CNC machining

center, and the main electrical components are famous brands.3. The

electric heating part automatically controls the temperature.4.

Rear drive belt5. Phase adjustment is synchronized with the

machine.6. The spunlaced fabric is unrolled in the center, and the

material is automatically spliced.7. Use the tube spray type to add

liquid, and the soaking mode to add liquid.8. The liquid addition

system includes a continuous stirring system and a circulation

system, and the amount of liquid addition can be adjusted.9. Raw

material cutting system, the degree can be adjusted by touch

screen.10. Non-woven fabric, packaging film has its own deviation

correction function.11. Host man-machine interface.12. Packaging

film tension control.13. Coding system, deviation correction system

(cloth and film).14. The packaging is formed, the size can be

adjusted, and the width can be replaced with abrasive tools. (If

you need different sizes, you need to customize and replace the

molder)15. Middle sealing system: traction preheating, longitudinal

sealing heating16. Horizontal sealing system: independent

mechanical cam control17. Finished product output.18. Safety

protection system: emergency braking system, blade safety,

plexiglass protection.(3) System features1. Drive mode:

Delta servo control system.2. The drive shaft adopts a

coupling.3. Timing belt for rear drive.4. Control system:

Delta control system5. PLC control system and monitoring

system.6. Automatic temperature control: Each part adopts

independent digital temperature indication, and the data can be set

according to different usage conditions.7. Electrical control

system: main circuit system, secondary circuit system, temperature

control system and tension control system, PLC control system and

other auxiliary systems.8. Product output: Conveyor belt is

adopted. The friction force is adjusted according to the different

speeds to ensure a good assembly line.9. Using aluminum alloy life

cutter.10. The main electrical appliances have passed CE

certification.(3)Product photos:(4)Factory Shows:(5) Package and

shipment(6) Certificates(7) Related productsFAQ:Q1:Are you a

factory or a trading company?A1:We are the manufacturer and

factory, specialized in wet wipes machine,packaging

machine,cigarette paper machine,balloon machine etc

industry.Q2:Where is your factory? How can I get there?A2:Our

factory is located in Nanan City, Quanzhou City,

Fujian Province, China.our nearest airport is JIN JIANG

airport, if you take plane, it will need about 1 hours from

Guangzhou,1.5hours from shanghai and 2 hours from Beijing. We will

pick you up from airport as well as the train station. Welcome you

and your team to visit our factory.Q3:What's your main

market?A3:Our machines are sold well in 30 provinces and

cities and enjoy high reputation in China. Also,it has been

widely exported to more than 60 countries, such as Korea, India,

Bangladesh, Russia, Pakistan, Brazil, USA, U.A.E, Kazakhstan,South

Africa etc.Q4:How is your factory doing in quality

control?A4:Quality is the most important principle. There are at

least twice test before shipment, the first is by our factory, the

second is together with customer. And also we will offer whole-life

service. What's more, all machinery has been passed CE testing.

Strictly testing the machine and arranging delivery after 100%

confirmation of no problem are what we always do.Q5:How about after

sales service?A5:The machines arrive at buyer's plant and

everything is ready for testing (including raw material ,electric,

air and relative project) ,seller will send 1 engineer /technician

to buyer's plant, buyer should pay for all relative expenses which

occur because of it (such as return tickets, local travelling fee,

the cost of accommodation, food and technicians' salary

USD100/day/person.) 2- Online technical guidance, operation video

provided. /* March 10,

Related products about Portable Single Piece High Speed Wet Wipe Making Machine for Travel Restaurant

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup