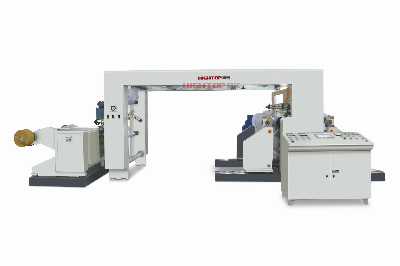

Product DescriptionKFQ Frame Shape Slitting Rewinding

MachineKFQ series model slitting and rewinding machine is our

Leader model of Gaobao(Hightop) Machinery. It is the

most automated, fastest and widely used of all our slitting

and rewinding machines. It is equipped with 3 pole main

servo motors, Automatic edge positioning correction system,

Siemens PLC and other internationally renowned brands of electrical

control systems. The stable running speed reaches 600

meters per minute, which can perfectly slit and rewind 40-800

gsm paper jumbo rolls into narrow width rollsPerformance and

characteristicsThe machine adopts synchronous control of three

servo motors, automatic constant tension structure, and center

surface rewind;The machine adopts frequency inverter to keep

running smoothly during accelerationAutomatic meter counting, alarm

and other functions;Winding adopts A, B air shaft structure, easy

loading and unloadingUnwinding adopts static analog ultrasonicRound

knife slitting waste edge automatic discharge deviceHydraulic

automatic shaft-less feeding frame structureKFQ series is

particularly suitable for processing webs with a width of

1300mm,1600mm,1800mm,2000mm. Therefore, it is used in a large

number of paper mills, paper converting plants, and roll slitting

service providers. Customer can choose suitable width of machines

based on production and materials specifications. In addition, many

paper product manufacturers such as paper bags, paper cups, paper

tubes, etc. also need to use KFQ slitter rewinder. It is

widely used in the field of printing and paper product

packaging. Roll To Roll ProcessLoading jumbo rolls in our

machine, setting up the knife position based on slitting width you

want to get. Then you will get several finished roll slitting

and rewinding with different sizes or same sizes then move it out

for production after. ApplicationProduct

Parameters ModelKFQ-1300KFQ-1600KFQ-1800KFQ-2000Max Width of

Unwinding1300mm1600mm1800mm2000mmMax Diameter of

Unwinding1700mm1700mm1700mm1700mmMax Diameter of

Rewinding1300mm1300mm1300mm1300mmMin. Width of

Slitting40mm40mm40mm40mmSpeed of Slitting 600

m/min600m/min600m/min600m/minGrammage40-800 GSM40-800

GSM40-800GSM40-800GSMPower Input380V 50HZ 56KW380V 50HZ 56KW380V

50HZ 60KW380V 50HZ

67KWDimension8500*3250*2700mm8500*3550*2700mm8500*3750*2700mm8500*4050*2700mmTotal

Weight13000KGS14000KGS15000KGS1700KGS Machine Photos

Machine Details Introduction Unwinding

stand: KFQ paper slitter rewinder machine adopt the

hydraulic control unwinding stand,which can easily pick

up 2000kg-3000kg weight and 1700mm diameter jumbo rolls.

There are different type of unwinding structure match with

different standard of weight holding requests, light structure

unwinding and heavy structure unwinding . Our machine design

is very flexible for meet clients' material specifications and

requests. For example,customer has paper rolls with different core

size like 3 inch 5 inch 6 inch or other size and need to change

core in the machine each time and spend more time if sizes

changes too much often.Conic Structure is able to solve this

problem, contact sales for getting more details. Contact our sales

for getting more details. Magnetic Powder Tension

ControlAbout of the unwinding tension control,we have three

options,magnetic powder brake,pneumatic brake,and servo motors

depend on material weight needed to be feeded. If you want to

know which type tension controlling system is better for your

material,please contact with our sales teams. Slitting

knives The slitting knives is enough strong to hold

knives and avoid trembling during machine running. Therefore, the

cutting accuracy is very high.One end of the shaft is fixed, and

the other end is rotatable. This design makes it very easy to

replace the slitting knives.The slitting knife is made of

high-speed alloy steel. It has the characteristics of high

precision and durability. Bottom Knife whole set of slitting

device is consist of 2 parts, up with round knife and bottom knife

down side Rewinding UnitRewinding shafts adopt A,B shaft. Two sets

motors drive rewinding shafts and output reasonable tension to get

high quality finished rewinding rolls. Cutting surface is smooth

and no wrinkles.Finished rolls can be automatic unloaded to save

operating labors. Rewinding UnitRewinding shafts adopt A,B shaft.

Two sets motors drive rewinding shafts and output reasonable

tension to get high quality finished rewinding rolls. Cutting

surface is smooth and no wrinkles.Finished rolls can be automatic

unloaded to save operating labors.

-----------------------------------------------------------Know More

About

Gaobao/Hightop------------------------------------------------------------ Company

ProfileZhejiang Gaobao machinery Co., LTD is a professional

manufacture of paper and plastic flexible packaging equipment

joint-stock company. It is located in Wenzhou,Zhejiang, China

(Building 9, No.9-11, Hairun Road, Binhai Development Zone,

Pingyang

Related products about Frame Type Roll to Roll Slitting and Rewinding Machine Forcoated Paper Ivory Board, Kraft Paper, Non Woven Fabric, Aluminum Foil Cutting 1300mm

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup