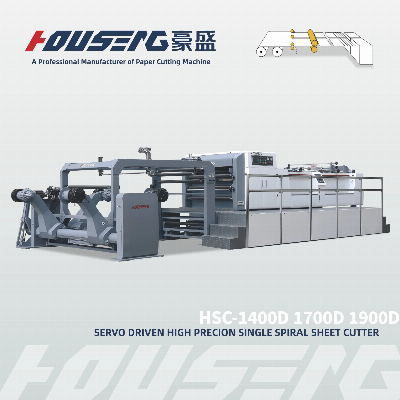

Product DescriptionAccording to HOUSENG Product

performance, the machine are mainly used for paper sheeting in

Paper Mill, Printing House,Packaging and etc, mainly process

including: Unwinding-Cutting-Conveying-Collecting.1.Upper knife

roller has the British cutter method to effectively reduce the load

and noise during paper cutting, and to extend the life of the

cutter. The upper knife roller is welded with stainless steel for

precision machining, and is dynamically balanced during high-speed

operation. Lower tool seat is made of cast iron integrally formed

and cast, and then precision processed, with good stability2.The

main machine wall through finite element analysis, mechanical

vibration analysis and optimization of the frame, uses the

high quality nodular cast iron for the integration of design, and

through precision machining, perfect the resonance phenomenon

between the transmission components, More stable in high speed

operation, improve the service life of the bearing parts.3.Touch

screen controls are used to set and display sheet size, count, cut

speed, delivery overlap, and more. The touch screen controls work

in conjunction with a Siemens PLC.4.Three sets of

pneumatic type slitting unit to have a high speed, smooth and

powerless trimming and slitting, with quick adjustment and locking.

High rigidity knife holder is suitable for 300m/min high speed

slitting .Application:Cutting reel (roll paper) into

sheetsTechnicals:According to HOUSENG MACHINE, are mainly used

for paper cutting in Paper Mill, Printing House and etc.Mainly

process including:

Unwinding-Feeding-Cutting-Conveying-Collecting .Our

AdvantagesUpper knife roll has the British cutter method to reduce

the load andnoise when the cutter extend cutter life.To steel

welding gave precision machining,and dynamic balance adjustment,

effectively reduce the vibration andnoise of the high-speed

operation. Rotary cutting knife is made of special alloy steel

precision machining,with long service life and easy adjustment of

the blade.Safety cover will automatically shut down when thesafety

cover is opened, ensuring safety.Dual position shaftless pivoting

arm unwind stand1)Max Reel Diameter: 1800mm2)Max Reel width:

1100mm/1400mm/1700mm/1900mm 3)Min Reel width: 300mm4)Core size

: 3"6"12" ( optional Mechanical chuck)5)Hydraulic driving :

3.5kw6)Clip arm move forward or back driven by hydraulic7)Clip arm

up or down driven by hydraulic8)Pneumatic brake system9)Roll with

related bracketSlitting knifeThree sets of slitting knife unit to

have a high speed,smooth and powerless trimming and slitting,with

quick adjustment and locking.High rigidity knife holder is suitable

for 300m/min high speed slitting.Motorized double decurler

systemEffectively remove the curl of the roll to make the paper

more flat,more conducive the paper roll tension stability,which

enable this machine practically to run thick board till

200-500gsm.Delivery and Auto Jogger SystemAutomatically goes down

when paper piling up to a certain height. (Chain type,

automatic up and down, more stable operation and service

life)Conveyor system with mult-stage:from high speed to low

speed.First to separate the cut paper quickly,and then overlap the

paper, collect and pile the paper.Electronic controlINOVANCE Servo,

INOVANCE PLC, Eaton, etc.The main machine structure (Knife holder

and holder stand)The main machine wall through finite element

analysis,mechanical vibration analysis and optimization of the

frame,USES the high quality nodular cast iron for the integration

of design,and through precision machining,perfect the resonance

phenomenon between the transmission components,make the operation

more stable, improve the service life of the bearing

parts.Transport departmentThe fast/slow speed belt is controlled by

the stepless frequency converter,which automatically tracks the

knife speed and adjusts the belt speed,so that the paper can be

perfectly overlapped. Auto counting and Automatic markingType:

Insert after counting preciselyFunction:After inputting number of

paper pieces in HMI,then it can work according to requirements.Auto

-EPC (Edge Paper Control)Precision sensing nozzle which easily

available and sensitive .Fast detects various web lines for EPC

system.Auto-tension controlPut the paper roll diameter and paper

weight number into touching screen,the tension will be controlled

by computer Automatically. Driving Motor system1, AC Servo

motor & encoder for cross knife2, AC motor & frequency transformer

for conveyor3, AC motor for up & down paper piling stand4, AC motor

for joggers5, AC motor for unwind stand6, AC motor for collecting

waste edge Option Configuration1.Blade -Tungsten Steel2.Cast

Iron Main3.Imports Of Electrical Appliances4.Pneumatic

slitting knife5.Dust removal 6.Color code

tracking systemMain Technical ParameterModelHSC-1100D /

1400BD/ 1700D / 1900DType of cuttingThe up knife cut

reciprocally and the down knife is fixedPaper weight range50-550

GSMReel stand load capacity:2.5

Related products about Houseng Roll to Paper Sheet Cutting Machine for Duplex Paper/Paperboard/Grey Paper/Kraft Paper

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup