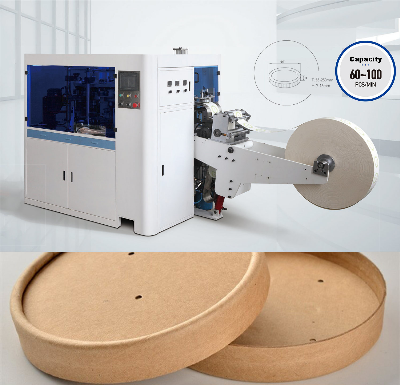

Product DescriptionPaper Lid Machine Feature 1. The

most recent contemporary technologies are included in this fully

automated, self-sufficient machine to improve efficiency and

accuracy. The entire process, including paper feeding, bowl-fan

wall sealing, oil and silicon lubrication, bottom punching,

heating, rolling, rimming, rounding, and discharge, is completed by

this machine. Auto feeding, creasing, molding, heating, folding,

and knurling are also covered.2.Round, straight-walled paper lids

are made using DCPL145. precise fit for the corresponding

application. the two types of stackables To provide your customers

with a comprehensive paper-based solution is the ideal complement

to cup or container packaging.3. The newest generation of lidding

machines, the DCLP03/04, is known for its high output, exceptional

fitting accuracy, and stability of closure. It produces very

dimensionally stable lids with closure beading that are perfectly

adapted to the cup or container packaging using tried-and-true

paper cup technology.The TINUO-branded lids machine make a frame

that is slightly flared and are appropriate for hot and cold

beverage cups as well as packaged cups.Machine Technical Data

TECHNICAL PARAMETERMODEL145 (Roll Feeding)145 (Sheet Feeding)200145

Leader / PL02LID HEIGHT7-15mm7-15mm12-16mm7-15mmLID

DIAMETER55-142mm55-135mm145-250mm55-122mmMATERIAL240-480g/m2 Single

or double PE coated paper/ Polished coated paper / PLA coated

paper.MATERIAL

THICKNESS0.32-0.55mmSPEED60-100pcs/min45-80pcs/min70-100pcs/min80-120pcs/minWEIGHT2800kg2800kg3000kg2800kgOVERAL

DIMENSION3250x1200x1850mm3250x1200x1850mm3250x1500x1850mm3400x1400x2050mmTOTAL

POWER12KWWORKING AIR SOURCEAir pressure: 0.4MPa; Air

output:0.1m3/min DCLP03/04 The TINUO-branded lids machine make

a frame that is slightly flared and are appropriate for hot and

cold beverage cups as well as packaged cups. TECHNICAL

PARAMETERMODELPL-03PL-04LID DIAMETER60-115mm120-185mmLID

HEIGHT17mm17mmLID

CURLING3mm3mmSPEED50-80pcs/min50-80pcs/minWEIGHT480kg480kgDIMENSION2840x1350x1900mm3225x1700x1900mmMachine

PartsSamplescoffee shopmilk tea shopdessert housecold drinks

shopcanteen Company ProfileOur HistoryIn 2010, in response to

global environmental protection and green packaging, we started

open up a new field of non-woven machinery, becoming the first

choice of customers. During the past many years, TINUO specializes

in manufacturing non-woven bag making machines, paper bag machines,

printing machines and different machines in packaging & printing

industry. In 2020, we made timely adjustments to the challenges

posed by the epidemic. Since 2021, we have constantly updated our

products to make them more intelligent and environmentally friendly

to provide the best quality, greenest and most cost-effective

solutions for the whole packaging industry as well as each of our

customers and always uphold the win-win cooperation concept.Our

FactoryWe have a factory with a professional R&D team and

production team to manufacture more advanced intelligent machines.

In the production process of bag making machines, we pay attention

to every detail and quality control of the production line. Our

large investment technology allows us to produce parts that meet

the exacting standard required to build a precision machines.Our

Advantage1.China Top 3 packaging

machinery Manufacturer2.We have 12 years of experience3.We

have more than 80 patents4.We are willing and able to customize

machines5.Our sales volume is the first place in the worldOur

CertificateClosely with international advanced technology

production technology, TINUO has more than 80 patents, due to the

changing of market demands, we willing and able to customize the

machines. All production from us have passed ISO9001:2000, CE, B.V,

SGS and GMC. With rich technology and capital resources, we pay

high attention to the new product innovation.Our ProductNON-WOVEN

PACKAGE MAKING MACHINERYPAPER PACKAGE MAKING MACHINERYPLASTIC

PACKAGE MAKING MACHINERYPRINTING MACHINERYLAMINATING

MACHINESSLITTING MACHINESGENERAL PACKAGE MAKING MACHINERYAfter

sales service Q & A--How to install the equipment?--Due the corona

breakout in global, the seller would not arrange engineer outside

to install, all the service would change to online

service. --If the corona finished,how to install? And how long

it will last?--The seller will send 1 engineer to install, test the

machine and train customers' workers in buyers'

factory. It will take about 1 week for the

entire installation and training. --What are the additional

costs of installation?--The buyer should cover engineers' salary,

visa cost, Round air tickets, accommodations, transportation in

buyers' country, food, medical care, safety cost, and related cost

happens in buyers' country. Also, the buyer should prepare enough

labor, electric wire outside the control panel and tools for

installations. --Who pay for the Engineer's Salary?And how

much?--The buyer pay for the Engineer's Salary.It's USD 80

Related products about Hot Sale Full Automatic Paper Soup Bowl Coffee Ice Cream Tea Cup Glass Lid Cover Making Forming Machine Price

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup