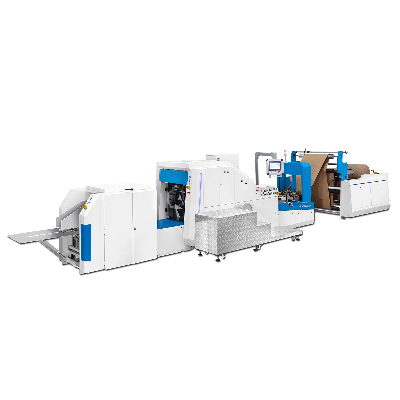

Product Description1) Full automatic square bottom paper bag

machine. From paper roll to well collected bags. 2)

Fit for bulk production of paper bags for food, underwear or

clothing.2) MITSUBISHI Touch screen interface and motion

Control, easy and efficient.3) Servo motor, photoelectric

correction, ensure the precision. 4) Unwinding equiped with

auto tension control & EPC system.5) Safety protection system.6)

Perfect after-sales service team to support.Product

Parameters Model DCZZ -B220 DCZZ

-B330 DCZZ -B400 DCZZ -B550 Paper bag

length191-430mm280-510mm280-600mm380-770mmPaper bag

width80-200mm150-330mm150-400mm220-550mmPaper bag bottom

width50-120mm70-150mm90-200mm100-210mmPaper

thickness50-140g/m260-140g/m270-140g/m280-140g/m2Machine

speed30-250pcs/min30-200pcs/min30-200pcs/min30-150pcs/minPaper bag

speed100-180pcs/min100-160pcs/min100-160pcs/min100-150pcs/minPaper

roll width290-630mm470-990mm510-1230mm630-1550mmRoll paper

diameter1500mm1500mm1500mm1500mm Machine power380V

3 Phase 9kw380V 3 Phase

11kw380V 3 Phase 15.5kw380V

3 Phase 18.8kw Machine

weight5600kg8000kg9000kg11000kgMachine

size8600*2600*1900mm9500*2600*1900mm10700*2600*1900mm13000*2600*2000mmApplication Widely

used, fit for bulk production of paper bags for food,

underwear and clothing, etc.Detailed Photos Packaging &

Shipping Company Profile Hot Selling

Machines DCWZ-XB700/XB800Fully Automatic Non Woven Bag

Making MachineDCZZ-A330/A400/A550Automatic square bottom paper bag

making machineDCTY-1200Computer Control High Speed Rotogravure

Printing MachineDCWZ-D500Non Woven U-cut Bag Manufacturing

MachineDCZZ-C270/C330V Bottom Paper Bag

MachineDCWZ-C700HS/C800/C800DLNon Woven Bags Manufacturing

Machine FAQQ1. How to install and operate the machine?Due to

the Global Epidemics we can not send the engineer , will

provide the manual and installation video.After the global epidemic

end, The seller will send 1 engineer to install, test the

production line and train customers' workers in buyers' factory. It

will take 1 week for whole installation and training.Q2. What

should we charge for your engineer?The buyer should cover

engineers' salary, visa cost, round-trip air tickets,

accommodations, transportation in buyers' country, food, medical

care, safety cost, and related cost happens in buyers' country.

Also, the buyer should prepare enough labor, electric wire outside

the control panel and tools for installations.Engineer's salary

is USD 80/day, depending on how the engineer make you

satisfied. The date he arrives and leaves shall be counted as paid

day.Q3. How long is your machine's warranty period?Warranty period

for the delivered equipment will be 12 months after completion of

erection but not later than 18months after shipment. In case any

item proves to be defective and the damage is confirmed by seller's

technicians within this period, the seller will at their choice

either send engineer to repair or supply a new one for replacement

free of charge on the basis of CNF delivery. The above item does

not include the parts, which have regular spares or the parts

damaged from normal wear, abnormal operation, improper maintenance

and inadequate civil works. The seller is not liable for any

production loss under any circumstances.Q4. How do we solve the

machine problem after your engineer leaving?Generally speaking,

there will be no problem after finish installing. In case you have

any problem. You can contact our after sales specialist at any

time. Engineers will help to take a solution video according your

description.Q5. How do you arrange packing for machine?As per

export standard, they will also be treated before delivery against

damage and rusting. /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about High Performance Square Bottom Making Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup