Paper Machine Clothing Spiral Dryer Screen Technical

ParameterStyle Sing loopsize (mm)Diameter (mm)Spiral

loop filament Diameter (mm)StringStrength

(N/CM)Width(mm)Weight(kg/m²)Air perm(m³/m²h)super large

loop 4.8 x 100.91.123003.031.6421000±1000large loop 3.8 x

7.00.680.920002.451.4018000±1000medium loop 3.5 x

6.00.680.920002.451.3116000±1000small loop 3.2 x

5.20.50.818001.870.9714000±1000 Other technical

parameter1.Shink percentage : under 135ºC ,<

1.5%;under 150ºC,< 2%.2.Dimension varation :length

:length < 20m,error +4cm;length > 20m,error

+5cm;width error:±1cm.3.Shrink percentage:< 1%.4.Width of edging

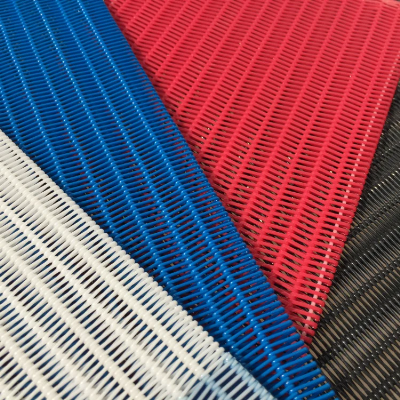

material:3.0~4.0cm.Sprial Dryer Screen specificationThe sprial

dryer screen is a high-breathing fabric applied to the dryer

section of the long-wire paper machine and the board machine. It is

made of various plastic synthetic fibers as the main raw material,

and is processed by weaving and heat setting. Special resin

treatment is carried out as needed, and the joints of the net are

also advanced. This fabric has heat resistance, abrasion resistance

and high air permeability. It has obvious effects on saving energy

and increasing vehicle speed. The dry mesh is highly adaptable and

can be used from tissue paper to cardboard.Spiral dry mesh is made

by using the latest international non-woven technology and

equipment. mainly used in the dryness part of paper-making

machines, drying process of printing and dyeing and other

industrials.Polyester is one of the most advanced drying and filter

materials in the world. The polyester spiral dry mesh produced by

our company uses high-quality hydrolysis-resistant polyester

monofilament, which is been formed, woven, finished and

shaped.Feature1) - Polyester spiral link dryer fabric belt with

high strength,good permeability,so this fabric belt is also used

forhigh-pressure press-filter water,horizontal belt

washer,pulp-liquor separator and mesh belt coal-washer etc.2) -

This fabric belt is widely used in all kinds of industries,such as

printing and dying,food,salt

industry,pharmacy,environmentprotection etc.3) - Polyester spiral

link dryer fabric belt is also used in papermaking industry,such as

paper pulp drying,forming,and papermaking sewage treatment

etc. Polyester spiral dryer screenPolyester spiral dryer

screen can be divided into three type: 1.Small loop,

suitable for fine paper .2.Midium loop, suitable for board &

packing paper .3.Large loop, suitable for board & packing paper

. Features1. Long service life, wear resistance and low net

consumption.2. High fatigue resistance, acid and alkali

resistance.3. The surface is flat, the tensile strength

is high, the gas permeability is good, and the heat transfer

efficiency is high.4. Easy to install and use, no trace on the

interface, not easy to deform during use. UseGenerally, the

drying part of the paper machine adopts a double-row drying

cylinder arrangement.The upper and lower dryingcylinders are

equipped with a dry screen, it will presses the paper against the

surface of the drying cylinder and leads the paperruns around the

dryer.By using the temperature of the dryer to evaporate the

moisture on the surface of the paper, and then takesthe wet air

away with natural ventilation or necessary mechanical ventilation,

so the paper is dried. MaintenanceIf the paper pulp contains

a large amount of waste paper, then the cleanliness of the dry web

is very important. Some impuritiescan adhere to the dry web so that

the ability to evaporate water is limited. Make the paper web

thinner and even appears paperholes. It is recommended to clean it

in time with high pressure or with professional cleaning

equipment./* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about High Quality Drying Fabric Sldf for Papermaking

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup