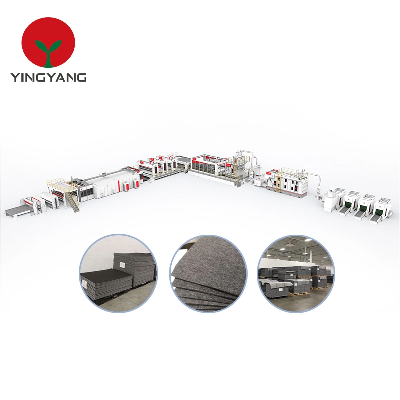

Automotive Interior Nonwovens Needle Punched Production Line

Product DescriptionIt coud produce medium and high grade needle

punched nonwoven fabric for automobile interior decoration blanket

etc.1. Applied fiber: PET and PP etc fiber Type: 2.5D-10D×

51-76mm2. Product specification: 100-800GSM3. Capacity: 200kg/h for

carding machine(take 6D fiber as raw material)4. Control method:

PLC and touch screen controlling systemTechnical process of the

production line:1. Bale openers 2. Pre-opener 3. Big Blender4. Main

opener 5. Hopper 6. Air-flow Vibration feeder7. Double-cylinder

carding machine 8. Cross lapper 9. Batt Feeder10. Pre-needle

punching machine11.5 sets of main needle punching machine12. Three

roller ironing machine13. Tension frame14. Winder Product net

width:≤4500mmProduct specification:≤1500g/ The completely sealing

design and the special air control system design makes the air

injected in between the cylinder and the wall board, to prevent

fiber causing issues with bearing wrap ups. And the special design

for the triangle area improve the airflow. Negative aire pressure

controls inside the card, which reduce greatly the cleaning

frequency and maintenance time. Modual design of the

anti-turbulence plate and machine frame, it is more convenient for

machine setup and maintenance. The cover is aluminum alloy sections

and the side plate of the machine cover is organic glass, and the

upper side plate and top cover is separated designed, which is

convenient for maintenance and easy to monitor the machine running

situation. Cylinder and all main rollers are rolled from

armor plate, which are treated with the special processing

technology ensures the straightness, runout and dynamic balance of

the roller without deformation. Very long lifespan and very high

accuracy Main production lineGeotextile production

lineAcoustic fiber board production lineAutomotive interior

nonwoven production lineSynthetic leather substrate production

lineThermal bonded wadding production lineThrough -air bonded

nonwoven production line Spun-bonded nonwoven production

lineSpun-laced nonwoven production lineFilter felt production

lineNeedle punched wipe production lineScrubbing pad nonwoven

production lineComforter filling production lineAirlay felt

nonwoven production lineGlass fiber production lineJute felt needle

punched production lineGeo-synthetic clay liners lamination

production lineDetailed PhotosCompany

ProfileCertificationsPackaging & ShippingAfter Sales

ServiceFAQ /* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Automotive Interior Nonwovens Needle Punched Production Line

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup