2. LateJW608 water-jet loom is currently represent the most

advanced technology of hydraulic models, developed in the same

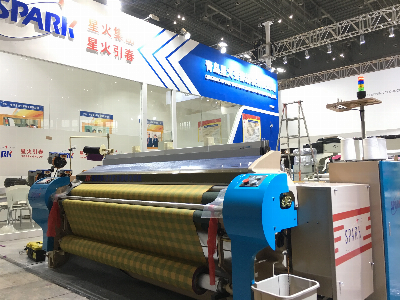

1.Water Jet Loom JW817Features:1. The whole machine has been

fully improved and strengthen from Let-off system, Shedding system,

Take-up system, Driving system, it is with the high-speed

continuously running capacity.2. The machine can be suitable for

wide fabric range: Fiber Fabric, Hydrophobic Strong Fabric,

Cotton Polyster, Short Fiber, Carpet, Silk Taffeta....3. Frame:

Lord wallboard adopts high-grades cast iron, main beam adopts

metatypical seamless steel tube, the whole frame will be much more

stable, reduction the shake when weave and run with high-speed, to

ensure the high quality and output of fabrics. At the same time to

make the tempering treatment to prevent it to be deformation of the

great wallboard, the middle wallboard, side cover.4. Expanded the

size of shedding connecting rod and lifting shaft, adopting double

bones and muscles, broadside(120mm) heavy stable frame, to

ensure the reliable of warp yarn shedding when weave the medium

weight fabric and run with high-speed, shedding is clear.5.Filling

Insertion System: Imported Nozzle, Water Pump Spring and One-way

Valve enhances the bundling of water spray, achieves picking

flexibility, reduces bobbin marks,warp damaged and water

consumption, decrease the weft yarn tention, prevents yarn

breakage, ensure the high quality of fabric and increase the

economic profit.Good quality main spare parts: 1.The bearing

for large board:German,Japan or SKF. 2.pump spring:AWA

Japan 3.Plug:Ceramic4.One way valve:AWA Japan

5.Nozzle:AWA Japan 6.Feeder:Mechanical or Electronic of

ROJ 7:Motor:China 8.Strip:Korea

9.Frame:strength 10.Transmission:Japan11.Oil

seal:TAIWAN 1 2.Cross Beam:Strength with

tsudakoma 8100 positive type let off models.The biggest advantage

is can weaving super thick fabric (600g/super dense fabric

(automobile airbag fabric) and ultra thin &light fabric

eliminate the stop marks.When weaving similar varieties speed can

increase about 100 rpm.Why the water jet so good??Because we take

reference of the air jet technology, developed a new type of

electric control system, positive back rest, belt connected

benefits (ear) axis part is not easy broken electric cabinet

is much more complicated than normal.Thick solid frame, which

guarantees the stability in the operation of high-speed, no

vibration.U type nozzle can realize water saving 10%-20%, good

cluster and weft insertion line is clear.All introduced, boot

operation, let the customer feel the low vibration.Find the speed

shows refers to the client on the screen.st YC910-190 air-jet

loom1) High weft insertion rate and high quality fabric is

attracting weaving customer, but due to e weaving phenomenon

of compressed air energy intensive and make comparison with our

client.Spark spring combination on jet loom over the years for the

work of energy saving result in improving the filling rate at the

same time, the energy fluctuation kongfu, to improve speed by 20%,

a 35% drop in gas, to raise the speed decrease gas consumption at

the same time, give full play to the advantages of the air jet

loom, at present our company energy-saving air-jet loom level has

been at the same level with JinKouJi and gas consumption in China

belong to the leading domestic level.Do the same varieties than

similar domestic textile machinery in saving electricity more than

4000 yuan/units.Reduce weaving enterprise operating costs.Improve

the market competitiveness for the enterprise.Example: 40 s weft

YC910-190 850 r/min, gas consumption is about 0.7 m after/min, CFM

is about 24.72) introduction of advanced machinery structure:In

order to adapt to high speed, USES the eccentric beating-up,

reduces the vibration, improve the beating-up force.Heald frame

beam with double shield beam structure, ensures the stability of

heald frame in high speed, reduce the amount of shaking, prolong

the service life of heald frame.New DSP (digital chip) electronic

control system integration suppliers by Siemens Shanghai Shanghai

yuanling together with our company design and development, its

components, most of them adopt Siemens components (high-end

customers electricity transmission volume of servo system is

introduced in this paper, using the German import schneider servo,

mid-range customers don't introduce, have asked, can be said with

Taiwan Xinjie)DSP system, large capacity, high calculating speed,

transmission is fast, not easy to interference, provide powerful

guarantee for high speed and energy savingLatest YC910-190 air-jet

loom1) High weft insertion rate and high quality fabric is

attracting weaving customer, but due to e weaving phenomenon

of compressed air energy intensive and make comparison with our

client.Spark spring combination on jet loom over the years for the

work of energy saving result in improving the filling rate at the

same time, the energy fluctuation kongfu, to improve speed by 2

Related products about Plain Water Jet Loom 190cm

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup