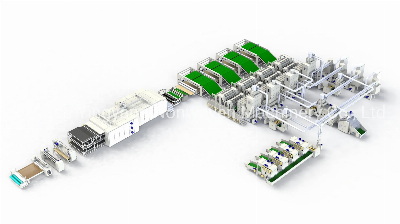

Precision and Efficiency Glue Bonded Wadding Production Line for

Automotive Industry Product DescriptionFunction and

Characteristics: This line usually includes several sets of

carding machine and cross lapper to product the down-like wadding

used as comforter, bedding liner, garment filling padding and

so on. With several sets of carding machine and cross lapper, the

product evenness is much better. And the line is very flexible for

the material fiber. For different carding machine, you can use

different denier fiber and you can save some manufacturing cost to

increase the product competitiveness. Besides, the bonding media is

resin glue, not low melt fiber. The product from this line is

more soft and more fluffy, better hand feeling. In the market, the

product is also very popular and very

competitive. Production process:Bale

opener→pre-opener→blending machine→main opener*2/3/4→vibration

feeder*2/3/4→carding*2/3/4→cross lapper*2/3/4→Glue spraying bonded

oven→cooling machine→Ironing machine→winder & cutterProduct

ParametersMain specification:Product net width≤4500mmProduct

specification60g/m2-500g/m2Material0.8-15 denier polyester fiber,

HCS fiberProduction Capacity600kg per hourDetailed Photos1. The

carding machine is capable to process siliconized fiber.2. The

structure of blending machine is special designed to mix

different kinds of fiber evenly so that the product hardness on

both sides can be same. 3. The oven is with special channel

and air circulation system to reduce the engenery consumption and

guarantee product quality about the product surface touch-feeling

and hardness. Company ProfileCertificationsPackaging &

ShippingAfter Sales ServiceFAQ/* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Precision and Efficiency Glue Bonded Wadding Production Line for Automotive Industry

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup