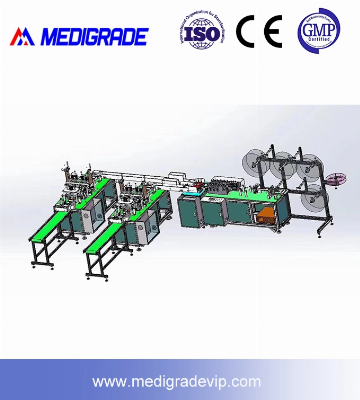

The production line is composed of a laminating machine, a flap

feeder and two ear belt welding machines. The following processes

are automatically completed through the equipment: manual feeding

roll - automatic conveying material - cutting iron line -

ultrasonic welding body piece - cutting body piece - splitting

material - flap - feeding - ultrasonic welding ear line - cutting

ear line - automatic blanking - belt line output.1) Machine size:

6500x3600x1990 mm (L * w * h) 2) power supply: 220V AC 3)

air source: 0.5-0.6mpa4) equipment weight: ≤ 2000kg5) control mode:

touch screen + PLC6) electrical components: solenoid valve (Adec),

air cylinder (Adec), touch screen + PLC, sensor (ohm Big brands

such as dragon and keienshi, gas connector (adeke or domestic),

regulating valve (adeke or domestic)7) capacity statistics function

is available on the touch screen of the machine, which can be

checked in real time8) safety: the equipment has grounding wire and

leakage protection switchtechnical parameterOutline

size6500mm*3600mm*1990mm ProductMask capacity≥100PCS/min Equipment

failure rate≤5% Control systemXinjiePLC Working air

pressure0.5-0.6MPa input voltage220V/50HZ Total

powerabout12KW This production line consists of 1 main body

welding machine, 1 turning / feeding machine and 2 ear band welding

machines, with 4 machines working together, as shown in the figure

belowNote: 1. The winder can put 4 rolls of materials to feed the

body piece welding machine;2. The body piece welding machine has

two functions of ultrasonic welding and cutting;3. The dividing

machine mainly transports the cut body pieces to two ear belt

welding machines; 4. The ear belt welding machine transports the

finished products by ultrasonic welding and cutting the ear

beltMain PartsNameBrandRemarkLinear slide railPMI/HIWI Linear

bearingYhda Ball screwHIWI/

PMI/TBI gearYhda Pneumatic componentsAirTAC servo

systemxinjie PLC systemxinjie SensorMACHER/

Panasonic InterfaceXinjie Equipment installation

environment requirements1. Independent grounding, reliable

grounding, grounding resistance less than 100 ohm;2. Power supply

voltage: AC220 ± 10% v; frequency: 50 ± 1Hz; total power: about

8.5kw;3. Environment temperature: 0 ºC ~ 45 ºC; humidity: less than

90%; moisture condensation is not allowed within the temperature

change range;4. Environment: avoid too much dust and corrosive

gases such as acid and alkali in the use environment; avoid sun and

rain to prevent affecting the performance of the equipment;5.

Install the equipment on a firm, reliable, non deformable and flat

concrete foundation to avoid abnormal vibration environment;6. Air

source requirements: 1, Pressure requirements: 0.5-0.8 MPa 2,

Compressed air shall be dry, clean and free of oil mist, water

vapor, etcShanghai Medigrade Industry Co.,Ltd Waigaoqiao Free Trade

Zone, Shanghai,China. 200137 medigrade.en.made-in-china.com

/* March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Automatic Non-Woven Fabric Flat Face Mask Making Machine 1+2

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup