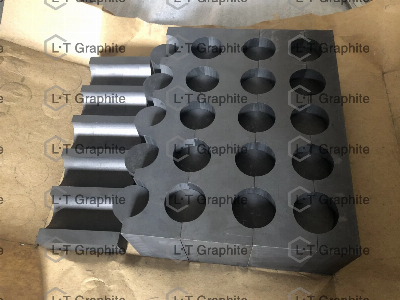

Graphite molds that do not react with metal are used for concrete

cutting tools

lttrade.en.made-in-china.comA: Company profile

L.T Group has a comprehensive product and technology

portfolio that focuses on four fields of graphite - ultrafine

particle graphite mould, graphite electrode, graphite

crucible, as well as other products mainly made of graphite.

Graphite materials exhibit unique properties such

as good electrical and thermal conductivity, heat and corrosion

resistance, low friction, and reduced weight while at the same

time maintaining high strength. Due to the shortage of energy and

raw materials, our high performance products made from

graphite are in increasingly high demand in industries. They

also play a progressively important role in everyday life, thereby

substituting traditional materials. B: Why choose

us Graphite mould plays a dual role in the process of

diamond tools manufacture:Heating element and Supporting mold.The

quality of graphite mold is very important, will directly affect

the next diamond tools' accuracy and appearance.So, which kind of

graphite mold is suitable for sintering diamond tools: a:

Good performance on conductivity and high rate resistivity b:

Enough Mechanical Strength c: Good performance on Oxidation

resistance d: Durable Our mold features:Raw

materials is very important, We only use Ultrafine particle

structure, High purity and High graphitization raw graphite

materials.Our finished graphite mold is: a: dense structure

and low porosity b: Fined surface and low rate

heat-deformation c: High mechanical strength and machining

accuracy d: Oxidation resistance and durableC: Product

features1.The processing materials are ultrafine granule structure,

high purity and graphite with high graphitization degree.2.High

hardness, good anti-oxidation performance and high machining

accuracy3.Good conductivity, high resistivity, sufficient

mechanical strength4.Small porosity and dense structure.5.Excellent

thermal shock resistance, conductive and thermal

conductivity.6.High temperature resistance, corrosion resistance,

acid and alkali resistance, good wear resistance.7.Surface can be

treated with anti-oxidation.D: Processing method1. Customer

provide design drawings.2. Our technical team will check, analyze

the drawings, and divide the drawing to reasonable parts if needed,

and prepare proper graphite blocks .Our mechanics will design and

customize grinding wheel.3. Our workers will grinding and polishing

graphite block according to the instructions of mechanics.This

process may need operating few times if needed.We will strictly

keep deviation within ±0.03-0.08mm.4. Then our packing team will

assembling different parts into a whole graphite mold.During

the assembling period, unqualified products will be picked out.E:

Attribute

tableDensity g/cm³1.75-1.9Resistivity μΩ·m≤18Compressive

strength Mpa40-80Porosity %≤26Elasticity

Modulus Gpa6-18Thermal expansion

coefficient 10-6/ºC1.47-4.25Ash

content %≤0.5Temperature

resistance ºC1000-1800/* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Graphite Molds Hot Pressing Diamond Toolings for Concrete Cutting Tools

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup