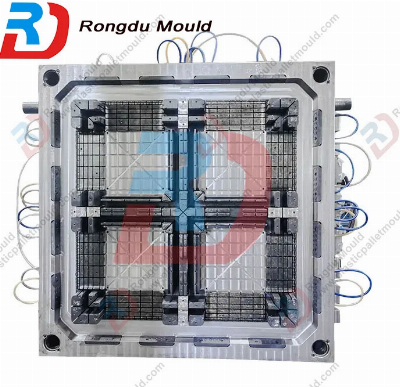

Double-Side Net Gird Window 4-Way-Entrance Shelf-Loading Plastic

Pallet MouldPallet is a good product for economic development, it

makes convenient for transportation. 1400x1200x150mm Double

Deck plastic pallet have many advantages, like using

hygienic plastic for raw material, which realize the green and

scientific manufacturing for plastic pallet. By the way, our skid

pallet owns good structure and beautiful shape, it received good

reputation on the market and our customer.Product Name: Double Deck

Plastic Pallet Mold Product

Size: 1400*1200*150mmProduct Weight: 25KG Plastic

Material: HDPE,PPDesign Program: NX(UG), Auto CAD, Solid

WorksMould Size: 1700*1500*1100mmMould Cavity: Single

Cavity Mould Steel for Cor/cav: HP20,H718,2738,

S136 Mould Steel for Slider/Insert Block: HP20,H718,2738,

S136 Mould Steel for Basement: S50C, HP20Injection System: 22

Tips Hot Runner SystemGate Type: Direct Gate TypeHot Runner System:

Chinese Brand, YUDO Brand, Mold Master BrandCooling

System: Beryllium-Bronze Insert & Water CoolingEjection

System: Ejection Plate & PinMould Surface

Treatment: Texture or High Gloss PolishingHydraulic Slider:

JUNFAN made in TAIWANMould Spare Part: DME or HASCO

StandardMould Tooling Tolerance: ±0.1mmMould Cycle

Time: 120SMould Life: 1 Million Shoots Mould Guarantee: 1

year Mould Deliver Time: 70 Days Product

Description Pallet NameDouble-Side Grid

Window Pallet Mould Pallet Size1400*1200*150mmPallet

Weight25.6KGCavity Number 1 Cavity Number for steel

Insert 8Pieces Plastic HDPE,PPDesign Program NX(UG),

Auto CAD, Solid Works Mould Description Mould

Size 1800*1800*1100mmMould Cavity Single Cavity Mould Steel for

Cor/cav Nitrided & Heat-Treated & Hardened

Steel HP20,H718,2738Mould Steel for Slider/Insert Block

Nitrided & Heat-Treated & Hardened Steel HP20,H718,2738Mould

Steel for Basement Nitrided & Heat-Treated & Hardened

Steel S50C, S45C Mould Raw Material Treatment Nitridation,

Quencher, Heat-Treated, Pre-HardeningInjection System24 Tips Hot

Runner Hot Runner System YUDO, Mold Master, Chinese Brand Cooling

System Beryllium-Bronze Insert & Water CoolingEjection System

Ejection Plate & PinMould Surface Treatment Texture or High Gloss

Polishing Hydraulic Slider JUNFAN made in TaiwanMould Spare Part

DME or HASCO Standard Mould Tooling Tolerance ±0.1mmMould

Cycle Time 120SMould Life 500K shoots Mould Guarantee 1 year

Mould Delivery Description Mould for T170 days Mould Deliver

Time 80 days Mould Installation Fixed Mould HS

CODE8480719090Package Wooden Case, mould would be Fixed

insideTransportation By Air or By Sea PaymentT/T, CIFCompany

Profile1. Background Rongdu Mould is one of the Pioneer for

plastic injection mould manufacturer. The Originator of us have

making mould since 1985 year and accumulated abundant experiences.

So we are specialized for manufacturing all kinds of plastic

injection mould, especially for PLASTIC PALLET MOULD, Crate Mould,

Plastic Chair Mould, Industrial Waste Bin Mould, Plastic Warehouse

Mould etc.Rongdu could manufacturer more than 600 sets of plastic

mould annually, including 500 sets of PALLET MOULD, like Nine

Leg Plastic injection Pallet mould, Skid Plastic injection Pallet

mould, Window Plastic injection Pallet mould, Double Deck Net

Plastic injection Pallet mould etc. "Making Mould More

Valuable " is our final achievement. We focus on the MOULD

QUALITY & DELIVERY TIME, providing stable mould within shortly

time for each customer. So Rongdu Mould won good reputations from

our old regular customer, and become one of leading for PALLET

MOULD MANUFACTURER.2.AdvantagesA. Rongdu have Strong Design TeamFor

every new mould project, we would have a meeting to discuss all

detail information, After product design will be confirmed, we

would make the mould design and Mold Main Flow Analysis, in order

to give customer reasonable suggestions and find best solution.B.

Rongdu have strict Mould Testing Standardsa. We would test every

mould raw material, ensure the mould raw material quality.b. We

would checkout the mould Tooling processing, in order to make the

each part of the mould could have precising dimension.c. Our

Assemble Mould Worker have more than 10 years working experience,

we are familiar with all details.C. Rongdu have Fast Mould

Delivery AbilityMould prompt be shipment is our most advantage, we

take high attention and responsibility for customer demand,

shipping each set mould timely to customer

country.3.Service Rongdu mould not only sale the mould to

customer, we pay highly attention Pre- & after- service. We would

discuss with customer together, like product structure, analysis

demould feasibility, analysis mould main flow. And we would have a

meeting before the mould manufacturing, in order to support more

valuable suggestions for our customer. FAQ-What Products Can You

Provide?Rongdu mainly manufacture:1111 Single-sided Nested

Pallet Mold with Nine-leg ; 1210 Single-sided Nested Pallet Mold

with Nine-leg ; 1210 Single-sided Grid Pallet Mold with Ni

Related products about 1400*1200*150 HDPE PP Double-Side Net Gird Window 4-Way-Entrance Shelf-Loading Plastic Pallet Mould

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup