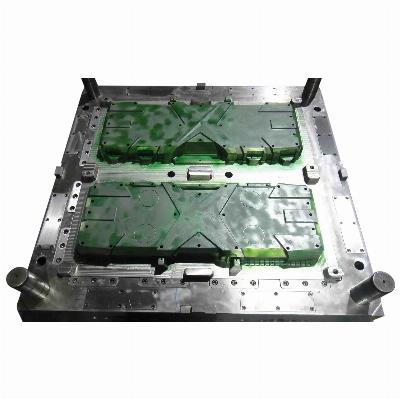

Product Description Toolbox plastic mould is an important tool

used to produce plastic products for toolboxes. Here we will

introduce the production process and production flow of toolbox

plastic mould in detail. I. Design stage In the design stage, the

design of the mold needs to be determined according to the shape

and size of the toolbox. The designer needs to use CAD or other

mold design software to make 3D models to ensure the accuracy of

the mold. The designer also needs to consider factors such as the

material, structure and processing difficulty of the mold to ensure

the quality and production efficiency of the mold. Second, make

mold core and mold shell Making mold cores and mold shells is the

core step of mold making. This requires the use of CNC machine

tools or other precision machines for machining. Different tools

and machining processes need to be used during the process to

ensure the accuracy and quality of the mold. After the production

is finished, the mold core and mold shell need to be finely

machined and tuned to ensure their mutual fit and precision. Three,

processing mold parts Machining mold parts include mold guide

pillars, mold holders, mold plates, etc.. This requires the use of

CNC machine tools or other precision machines for processing to

ensure the precision and quality of the accessories. After the

processing is finished, fine processing and debugging are needed to

ensure the mutual cooperation and precision of the accessories. IV.

Assemble the mold Assembling the mold is to assemble the mold core,

mold shell and mold parts together to form a complete mold. This

requires fine machining and debugging to ensure the precision and

quality of the mold. After the assembly is completed, the mold

needs to be tested and adjusted to ensure its normal operation and

production efficiency. V. Surface treatment Surface treatment is to

enhance the wear resistance and service life of the mold. This

requires processing processes such as surface polishing, plating or

coating to ensure the quality and reliability of the mold. Six,

mold testing and adjustment Mold testing and adjustment is an

important step to ensure the proper operation and productivity of

the mold. This requires different testing and adjustment processes,

such as mold testing, adjusting pressure, etc., to ensure the

normal operation and productivity of the mold. The above is the

production process and production flow of tool box plastic mould.

This requires several stages of processing and debugging in order

to produce a high quality mold. The production process needs to pay

attention to the choice of material and process to ensure the

quality and production efficiency of the mold. For the quality

control and management of toolbox plastic mold manufacturing, we

can start from the following aspects: 1. Quality control of raw

materials In the manufacture of tool box plastic moulds, the

quality of raw materials directly affects the quality of the final

product. Therefore, we need to carry out strict quality control on

raw materials. Specific measures can include: - Selecting regular

suppliers to ensure reliable sources of raw materials - Testing the

raw materials to ensure that they meet the relevant standards and

requirements - Establishing raw material quality files to record

the test results and usage of each batch of raw materials 2. Design

quality control When designing plastic molds for toolboxes, we need

to take into account the use scenarios and requirements of the

products, as well as the problems that may occur during the

manufacturing process. Therefore, we need to carry out strict

quality control on the design. Specific measures may include -

Review of the design to ensure compliance with product requirements

and manufacturing requirements - Simulation and analysis using

software such as CAD/CAM to ensure the feasibility and optimization

of the design - Establishing a design quality file to record

important information and decisions during the design process 3.

Manufacturing quality control When manufacturing plastic molds for

toolboxes, attention needs to be paid to problems that may occur

during the manufacturing process to ensure that product quality

meets the requirements. Specific measures may include -

Establishing manufacturing processes and standards to ensure that

every step of the process meets the requirements - Inspection and

acceptance of each process to ensure that the manufacturing quality

meets the requirements - Establishing manufacturing quality files

to record important information and decisions in the manufacturing

process 4. Inspection quality control After the manufacturing of

toolbox plastic molds is completed, the products need to be tested

to ensure that the product quality meets the requirements. Specific

measures may include - Establishing product testing standards and

methods to ensure reliable testing results - Testing and acceptance

of each product to ensure that product quality meets the

Related products about Tool Box Plastic Mould Customization

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup