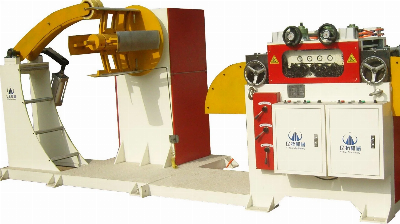

Product DescriptionMain Features1. Available in two

configurations, TGL models are much more flexible.2. Designed

for a metal plate from 1.0 to 6.0mm.3. Decoiler and straightener

are both powered. RHW models can smoothly deliver the metal strip

to automatic feeding equipment.4. Multiple hardened and ground

rolls have been hard-chrome plated.5. TGL models utilize 9

straightening rolls with 4 pinch rolls for superior straightening

capabilities on a variety of applications.6. All straightening

rolls are power-driven through a precision gear train without

scratching the surface finish.7. The pressure and pneumatic release

of inlet pinch rolls that rotate synchronously with straightening

rolls assist in material insertion.8. Equipped with an inverter,

RHW models use a manually adjustable speed control knob to make the

operator set the payoff speed.9. The micro-adjustment device

individually adjusts the depth of upper rolls by worm and gear.10.

Decoiler press arm and support arm prevent the coil from

loosening.The head of the straightener1, The head adopts the design

of a parallel roller, the upper 3 rollers/lower 4 rollers, a

totally 7 refined roller structure2, Adopting four-point fine

adjustment, which is more suitable for processing high-precision

products. Four-point independent pressure is used to adjust the

pressure of the feeding wheel for incoming and outgoing materials,

which can effectively prevent deviation and deformation of

materials.3, Support roller adopts galvanizing roller without

power, material integrated forming, surface resistance to

scraping grinding, using mechanical bearings, rotating flexible and

durable.4, It adopts a cast iron hand wheel, and its surface is

electroplated, it is the most traditional hand wheel.5, The

transmission part is protected by the protective cover on both

sides, equipped with a window for convenient observation·Rack

section1, The equipment adopts a decoiler and straightener combined

together, improving the utilization rate of the site.2, The

rack is designed with a cantilever beam, and all the plates are cut

by laser plasma, with high precision and good

interchangeability.3, All plates are cut by laser plasma with

high precision.4, The overall structure is simple, general

technical workers can assemble and replace equipment parts,

convenient and fast, greatly reducing the maintenance

cost.·Straightener roller1, The straightener wheel is made of solid

bearing steel, thickened and electroplated after intermediate

frequency, and the surface hardness is not low HRC58, to ensure the

durability of the material.2, Forging round steel with GCr15, after

preheating treatment( spheroidizing annealing), then turning,

milling, intermediate frequency treatment, rough grinding and

cooling stabilization, then fine grinding, finally electroplating,

maximize the guarantee of precision degree, concentricity,

smoothness, and hardness, extend the service life of straightener

roller.·Drive gearThe gear processing process includes the

following process: gear blank processing-tooth surface

processing-heat treatment-Tooth surface finishing.Raw parts are

mainly forged parts, By normalizing treatment, improving its

cutting, to facilitate cutting; according to the gear design

drawings, rough machining, and then half fine processing, lathe,

rolling, and gear shaping, make the gear basically formed; then by

heat treatment to improve the mechanical properties.According to

the design requirements of the drawings, the final finishing,

finishing benchmark finishing the tooth type. After the above

treatment, our gear grade can reach grade 6, with high wear

resistance and strength high, and long service life.·Power section1

Adopt model 80 worm gear vertical reducer, use the speed converter

of gear, reduce the rotation number of the motor to desired

rotation number,and get the mechanism with larger torque.2, Adopt

vertical motor, low vibration, low noise, fixed rotor part adopts

pure copper coil, life is 10 times of ordinary coil, both ends are

equipped with ball bearing, low friction, low temperature.Electric

control box1, Adopt silver alloy relay, full copper coil,

flame retardant safety base, long-lasting and durable.2, Adopt

safety protection adjustment circuit time delay, silver alloy

contact, various and dial, satisfied different delay ranges.3, The

switch adopts sliding contact, with a self-cleaning function,

normally open and normally closed contact adopts separate bonding

structure, can work with different poles, is equipped with

anti-rotation positioning, and stop loose mounting gasket.4, Adopt

a self-duplex flat button, the force is light, the key range is

moderate, and the building block type combination structure. The

contact is made up of keto-base composite points with strong

conductivity and a large current, with a life span of up to 1

million times. Product Parameters

TypeTGL-300HTGL-400HTGL-500HTGL-600HTGL-700HTGL-800HMax.width300mm400mm500mm600mm700mm800MMThickness0.6-6.0mmCoil.

Related products about Metalworking Machine Tools Equipment Steel Sheet Leveling Uncoiling Metal Straightening Machinery

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup