Product DescriptionProduct namePermanent Mold

CastingMaterialA356,A357,A380,A319,AC4B,ZL107,ZL101,AlSi8Cu3,AlSi7Mg0.3CertificateISO9001:2008,IATF

16949;ISO 14001Heat TreatT6,T61,T7ApplicationAuto part, agriculture

part, motorcycle, engineering machinery, medical machinery, general

machinerySurface finshas costumers requirementAdvantageSuperior

quality and price competitivenessProcessPermanent Mold

Casting/machining/surface treatEquipment5 sets with inclinable

worktable and 5 sets with horizontal worktableProduct

SizeRound part size: MAX φ300 mm Irregular part size:

MAX 600L*400 WTool capabilitiesCasting simulation, Tooling

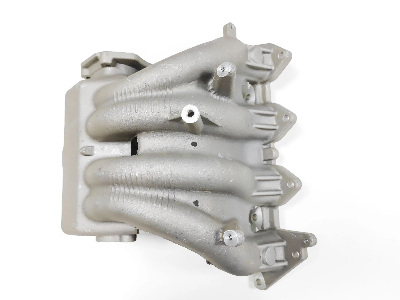

designProcess DescriptionPart DisplayManifold Intake

Product

developmentWhat shall we do after recieve new order from

customers?Our companyMajor CusotmersWhy CUTI 1,Superior

quality and price competitivenessWith abundant resources of quality

suppliers, we can choose the most specialized suppliers according

to different customers and product requirements, with both cost

advantages and excellent quality performance.2,Fast product

development capability with our engineering teamWe are not just a

trader. Our engineering team with 20 engineers and technicians

proactively participate in project development to provide technical

support, establish efficient and professional communication between

customers and suppliers, greatly reducing the cost and lead time

for new project development.3,Supplier Quality ManagementWith many

years of experience working with global leading customers in

various industries, we provide effective quality audits(VDA6.3,

IATF16949, ISO9001) and improvements to suppliers to meet

customer's requirements, follow APQP - PPAP process for new product

development, problem solving in the form of 8D reports, and

continuously help suppliers to improve their process control

capabilities and quality performance. 4,Advanced laboratory of

our ownOur own laboratory equipped with advanced equipment from

Zeiss, Olympus and Mitutoyo, with comprehensive product measuring

and testing capabilities. We also established cooperation with

third-party testing facilities to monitor product quality in all

aspects.5,Rapid on-site responseWe have set up on-site quality

inspectors at our major suppliers to monitor quality performance

and production status in real time on a daily basis. Our team can

be onsite in the factory within 12 hours after an issue

has been identified and begin finding a solution. ,6,North America

Sales Team and WarehouseCMT's North American marketing sales team

reaches out to various industries to obtain diverse product RFQs,

providing suppliers with plenty of quotation opportunities and

after-sales service in the market. Safety stock is established in

our own warehouse in North America which greatly reduces delivery

risk. /* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about CNC Machining/Manifold Intake/Aluminum Alloy High Pressure Die Casting/Precision Machining

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup