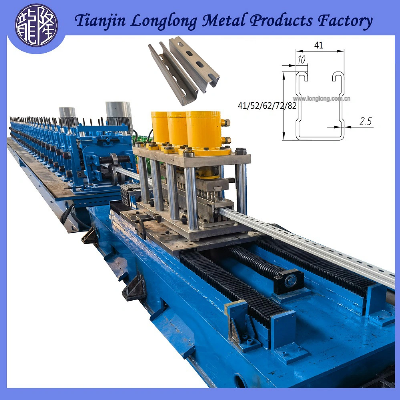

2% off 41 U Steel Purlin Roll Former Solar Mounted C Steel Bracket

Roll Forming Machine ManufacturerWe main research & development and

manufacturing cold bending roll forming machines since 1991.If you

supply for photos of steel products and technical drawings, we can

make it to order and meet your requirements.Main Technical

dataNo.ItemParameters1ModelLL-70-22ST2Suitable materialGalvanized

steel & Cold rolled steel sheet3Thickness1.8-3.0mm4Total

SpeedAbout 30~42 m/min including Punching5Total powerAbout

78.5KW6Cutting TypeHydraulic,& Servo tracking7Forming step22

steps8Dia. of shaft¢70mm9Shaftthermal refining HN250-28010Driving

methodCommutator drive; Soft coupling output.11rollerCr12Mov, Salt

bath quenching HR58-6212ReducerK87 series reducerMain components

list -- Whole LineNo.ItemUnitQty1DecoilerSet12Roll Forming

machineSet13PLCSet14Hydraulic stationSet15Cutting

deviceSet16Punching deviceSet17CollectorSet1 Production

process flow chart:uncoiling → Leveling → roll forming → servo

tacking punching & cutting → collectionProcess descriptionThe type

production line can produce variety of sizes steel through changing

punching molds.cutting, all sizes of punching and cutting

length are measured directly by the counter, and the size is

set arbitrarily in the man-machine interface.U41 series Steel

Purlin Roll Forming Machine Production Line:It can produce 41*

41/52/62/72, 4 types U purlin in one line.Green production line :

12 holes/ time ,32 m/min include punchingBlue production line

: 18 holes/ time, 40 m/min include punchingOther Solar

Tracker Steel Purlin Roll Forming Machine Production Line1.C Steel

Purlin Roll Forming Machine Production Line,22~27m/min include

punching2.Hat Profile Roll Forming Machine Production Line,24m/min

include punching3. M Profile Roll Forming Machine Production

Line,24m/min include punching5. Z Profile Roll Forming Machine

Production Line,24m/min include punchingSuccessful

projectAdvantage1.We are manufacturer and have export

entitlement.2.We have more than 30 years' experience, our products

have been exported to more than 80 countries all over the

world.3.We supply manufacturing, design, installation, after-sales

and other services.FAQs1.Do you have after sales support?Yes, we

are happy to give advice and we also have skilled technicians

available across the world.We need your machines running in order

to keep your business running.2.How to visit your company?a. Fly to

Beijing airport, we can pick up you.b. Fly to Tianjin Airport, we

can pick up you.3.How to get a quotation?a. Give me the profile

drawing and thickness, this is the important. If no, I will suggest

you some.b. Other specific requirements are welcome, such as the

speed, power and voltage you want.4.You are trade company or

factory?We are factory. Welcome to our workshop for visiting.5.Can

you be responsible for transport?Yes, please tell me the

destination port or address. We have rich experience in

transport.6.How long the machine could be made?Normally speaking,

common roll forming machine could be made within 45 working days.If

you need machines in a hurry, we can make it for you less than a

month./* March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about 2% off 41 U Steel Purlin Roll Former Solar Mounted C Steel Bracket Roll Forming Machine Manufacturer

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup