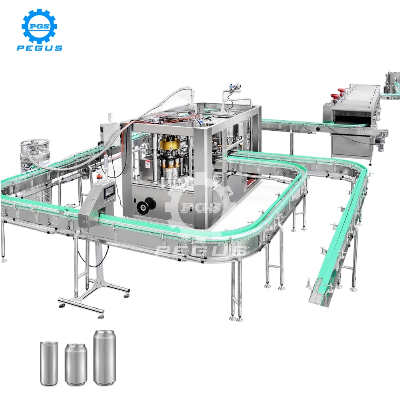

Product DescriptionCan Filling Machine [ Filling Capping 2 in 1

type ]This machine is an equipment developed by Pegus Machinery,

which digests and absorbs domestic and foreign (airless can

filling and sealing machine). It uses atmospheric pressure to fill

the original raw material. After the can is set up, the filling

sink and the air are centered, the empty can is lifted and sealed,

and the mouth of the filling tiger is automatically opened at the

same time, and the filling is stopped when the filling liquid level

blocks the air return pipe of the valve.It is used for filling

carbonated beverage in cans, such as beer, cola, energy drinks and

soda water. This can be used for different material of cans,

such as plastic, iron, aluminum and so on, and the different size

of cans is allowed. We can design the equipment according to

your requirements, filling and sealing is the overall designed

power system by filling sealing system to ensure that both the

absolute synchronization and coordination.Full automatic energy

drink canning equipment / carbonated soft drink beverage aluminum

can filling sealing machineWe supply complete solution for pop cans

/ tin can filling production line, including can depalletizer, can

rinsing machine, can filling & sealing monoblock machine, leakage

check, liquid nitrogen dosing machine, can warmer, film wrapping

system.Wide range of applicationsNow our products are widely used

in food, juice, beverages beer and other industries. They are used

inproduction's quality inspection, classification, as well as in

the product packaging weigher test.They had helped customers

togreatly reduce the labor costs, to improve the production

efficiency, and greatly to improve the percent of pass, help

customers to improve the industry competitiveness.Detailed

PhotosCan washing PartFunction : washing cans inside and outside

dust .1. All 304/316stainless steel rinse heads, water spray style

inject design, more save water consumption and more clean2. 304/316

Stainless steel Gripper with plastic pad, ensure minimal bottle

crash during washing3. 304/316 stainless steel washing

pumpFilling PartFucntion : filling beverage into cans.1. SUS304/316

Stainless steel high precision filling nozzle2. Filling volume

adjustable in fine rank, same liquid level after filling3. All

SUS304/316 stainless steel contact parts & liquid tank, fine

polish, no death corner, easy to clean4. SUS304/316 stainless steel

filling pumpCapping PartFunction : put caps on bottle .1. Place and

capping system, electromagnetic capping heads, with burden

discharge function, make sure minimum cans crash during capping2.

All SUS304/316 stainless steel construction3. No CANS no Sealing4.

Automatic stop when lack of Cans and CapsProduct ParametersWe have

a variety of modes of filling machine for your choice, can well

meet your needs

Model GF12-1GF18-4GF24-6GF32-8Capacity 1200-1500cans/hour5000-6000

CPH7000-9000 CPH10000-12000 CPHCan

Volume200ml-1000ml200ml-1000ml200ml-1000ml200ml-1000mlCan

diameater50-70mm50-70mm50-70mm50-70mmBottle

high120-170mm120-170mm120-170mm120-170mmMachine

power1.5KW2.2KW3.7KW5.5KWMachine

size175x120x195CM305x175x220CM340X195X220CM350x235x225CMCompany

ProfileOur AdvantagesAfter Sales Service1. Installation, debugAfter

equipment reached the workshop of customer, place the equipment

according to plane layout we offered. We will arrange seasoned

technician for equipment installation, debug and test production at

the same time make the equipment reach the rated producing capacity

of the line. The buyer need to supply the round tickets and

accommodation of our engineer, and the salary.2. TrainingOur

company offer technology training to customer. The content of

training is structure and maintenance of equipment, control and

operation of equipment. Seasoned technician will guide and

establish training outline. After training, the technician of buyer

could master the operation and maintenance, could adjust the

process and treat different failures.3. Quality guaranteeWe promise

that our goods are all new and not used. They're made of suitable

material, adopt new design. The quality,specification and function

all meet the demand of contract. We promise that the products of

this line could storage for oneyear without adding any aseptic.4.

After salesAfter checking, we offer 2 years as quality guarantee,

free offer wearing parts and offer other parts at the lowest price.

Inquality guarantee, the technician of buyers should operate and

maintain the equipment according to seller's demand, debug some

failures. If the problems are still can not solve, we will arrange

technician to your factory solving the problems. The cost of

technician arrangement you could see the cost treatment method of

technician. After quality guarantee, we offer technology support

and after sales service. Offer wearing parts and other spare parts

at favorable price; after quality guarantee, the technician of

buyers should operate and maintain the equipment

Related products about Automatic Beer Cans Rinser Filler and Seamer Beverage Can Filling Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup