Product descriptionFrench Fries

Production Line The production line consists of steam

peeler,hydro cutter,blancher,drver,fryer,deoiling

machine,freezeland packing machine.lt has a maximum automation and

achieves continuous and large-scale production with a production

capacity up to 10 tons/hour.

Product featurePerformance and Benefits1.Meet the

needs of large-scale production with a capacity 10tons/hour.2.Low

energy consumption and high efficiency,saving energy

significantly.3.Fully automated design to minimize labor

costs.4.High grade sanitary design for easy cleaning and

maintenance. Technological

process1.Loading and conveying2.Stone cleaning machine: remove

stone and soil attached to the surface of the potato.3.Steam

peelers: Operate steam equipment to quickly remove the skin of

potatoes.4.Roller cleaning machine: the potato surface residue

potato skin and starch clean away.5.Manual selection table: pick

out the broken potatoes and cut the potatoes that are too

large.6.Water knife cutting: Cut the potatoes into strips according

to the established size standards.7.Wafer picker: Screen out the

potato strips that do not meet the standard size.8.Blanching: Boil

the potato strips at the right temperature and remove the starch

from the surface of the potato strips.9.Color protection: This

process keeps the fries from changing color for at least two

years.10.Remove water to dry: Remove water from the surface of the

potato strips.11.Fry machine: Fry potato chips, so that the French

fries outside crisp inside.12.Air cooling ,quick freezing and

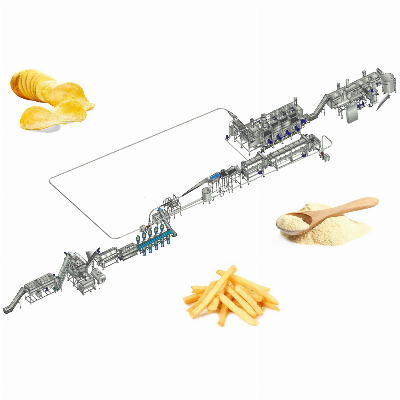

package. Equipment

picture

Company profile

Shanghai Uwants Technology Development

Co.Ltd.,located in Minhang District, Shanghai, was built up and put

into operation in May, 2014. It focuses on the R&D and

manufacturing of complete food production line, potato peeling and

cutting line and French fries production line. The company has two

production bases, covering a total area over 120 mu a workshop area

over 40000 square meters and more than 180 employees. Closely

following the development trend of global cutting-edge science and

technology and collecting the knowledge of world food process, the

full production lines manufactured by the company has the

characteristics of high automation and low labor intensity, so as

to achieve a result of simplification, continuity and energy saving

during production. In order to better improve

the user experience and product performance, the company introduced

advanced equipment and production concepts from developed countries

such as Europe and the United States, passed through the ASME

certification, and worked closely with industry leaders at home and

abroad to successively develop steam peeler and water cutting line,

which solved the problems of large-scale and automation faced by

the potato processing industry, to improve production eciency and

production yield significantly. The company

adheres to the principle of "Quality and Service First", always

provides users with satisfactory solutions and services. We look

forward to sincere cooperation, mutual exchange, coordinated

development with our customers for a prosperous future.

FAQ1.What are the payment terms?T/T,L/C

and trade assurance are acceptable,T/T will be more appreciated,30%

deposit before production,70% balance before shipment.2.What is the

delivery time?At least 2 month after the deposit recipit,depend on

how many machines included in the line.3.How to pack the

machine?Standard packaging4.How to install after the machines

arriving destination?Our engineer will go to customers site if you

need,but need to pay installation fee accord with the

contract.5.What's the capacity you can do?Always produce depend on

customers' requirement./* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Automatic Potato Chips Production Line Frozen French Fries Making Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup