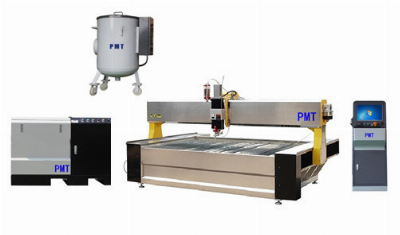

Application and advantages of PMT waterjet cutting:PMT Waterjet

Cutting Machine is an effective tool for any shape of artistic

creation. The traditional cutting method is saw cutting only in a

row. When cutting the curves, the model should be made according to

the size and then polished. Waterjet Cutting Machine can cut any

shape of models under the control of the CNC program. 1. Smooth

cutting quality is perfect.2.The cutting accuracy of waterjet

cutter is up to 0.1mm. Edge joints are regular, and water jet

cutting can also make very complex puzzles and murals. 3.Cutting

speed is fast, and product consistency and interchangeability are

very good.4. Drilling, cutting and forming can be done at once. 5.

Improve the working environment and reduce the impact of dust and

noise on the operator.6. Waterjet cutting is a cold cutting that

does not damage the internal structure of the material. 7. It is

the only machine for processing composite materials and fragile

porcelain. 8. Waterjet Cutter can cut metal, rubber, foam, plastic,

composite materials, stone, ceramic tile, marble,glass, etc.

Product DescriptionControl Theory of Servo Direct Drive

Pump:PMT25DDP waterjet that is Direct drive pump is a device that

directly converts electric energy into hydraulic energy by a

crankshaft connecting rod mechanism, and the energy conversion

ratio is as high as 97% or more. The power conversion ratio of the

conventional asynchronous motor is 80% and that of permanent-magnet

servo motor is 97%; therefore, replacing asynchronous motor by

permanent-magnet servomotor greatly improves the power consumption

of the intensifier, keeping the conversion rate above 90%; while

the energy conversion rate of the conventional hydraulic

intensifier is only 56% (This conversion rate is only in the state

of full work.).In the traditional hydraulic system, the

asynchronous motor still keeps turning when the waterjet is not cut

(such as the movementof the cutting head, changing the cutting

material, etc.), and the oil pump is still in working state.

Although the pressure of the oil pump is not high at this time,

still there is 30% power loss. Even servo power oil pump is used,

the asynchronous motorstill has 30% loss if it maintains its own

rotation and power magnetic field. Servo Direct Drive Pump

Advantages1. Selection of motors: 18.5kw, can save power

consumption above 60%, 12DEGREE/HOUR electricity consumption if

work continuously 2. Pressure conversion methods: can save energy

about 35%. 3. Cutting efficiency: greatly improved by 10%-20% 4.

working noise is 40DB 5.it is very good for glass and ceramic tiles

waterjet cutting. PMT25DDP

Pump Dimension(L*W*H)1600*980*950mmWeight 600KgPower

rate 18.5kw/25hpMax. pressure 380Mpa /3800barWorking

pressure250-320MpaMax. Flow rate3.5L/minΦ of

orifice 0.25-0.30mmPower supply380V 50hzCooling systemWater

chiller Cutting TableAttributes: PMT waterjet cutting table

consists of transmission part with X axis, Y axis and Z axis, water

tank, cutting head, lubrication part and servo driving system.

Gantry mechanical structure is fit to large size machines, long

running distance of X and Y axis, suitable for processing a variety

of complex big size parts. 2 Working Table &

Controllor Model16162516302040206020Dimension(mm)2650*2150mm3400*2150mm4250*2300mm5250*2300mm7250*2300mmMax.

cutting

range1600*1600mm2500*1600mm3000*2000mm4000*2000mm6000*2000mmTravel

of Z axis180mmServo systemJapanese Brandball-screw

linear-railTaiwan BrandRe-positioning accuracy±0.025mm/mCutting

accuracy±0.1mmMax. running speed15000mm/minCNC

Controller Power supplyAC220V 50/60Hz Drawing

systemAuto-CADComputer systemWindows 7Function Moving

controllerscreenApply 19 inch LCDWater jet

softwareNC-Studio-V10Support DXF file and anyauto programming

software to produce NC code3-Axis cutting system3 Three-axis

cutting system Re-positioning

accuracy±0.02/1000mm Cutting accuracy±0.15/1000mmMax.

prussure 420mpaOrifice typeSM2Nozzle

type6.35*0.76/1.02*76mmrunning travel of Z axis180mmMax. running

speed 15000mm/minapplicationNormal Cutting Training for

Waterjet Equipment 4 Technical Training1basic working

principle of the super-high pressure water jet cutting

machine2working principle of the high-pressure system and

supercharge3replacement of the high-pressure sealed, low-pressure

sealed and high-pressure parts4maintenance of the high-pressure

system and judgment and troubleshooting of common failures5CNC

Programming&operation&operation of the NC cutting

platform6daily maintenance of the NC cutting platform7equipment

installation8abrasive control and transportation operation and CNC

communication9operation of the CAD / CAM software and CNC

communication10working principle, maintenance and judgment and

troubleshooting of common failures of the main high-pressure

functional parts, high-pressure water switches and abrasive cutting

headService:5 After-sales Service1Free warranty for the whole

machine for one year or 2000 high-pressure/hour 2Traini

Related products about Water Jet Cutter Pmt25DDP-1616 Waterjet Cutting Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup