Hydraulic Static Pressure Paver Interlocking Building Clay Soil

Automatic Cement Fly Ash Sand Concrete Block Hollow Brick Making

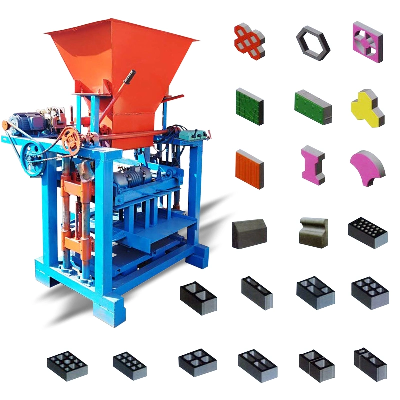

MachineryProduct DescriptionThe manual block-making machineis one

of our sell best block-making machines, suitable for making all

types of hollow blocks, solid blocks, pavers, curbstones, and

so on. Its main characteristic is saving electricity and saving the

workforce and can produce hollow blocks on the cement floor without

any pallets, especially suitable for small factories.Production of

various brick types, Support mold customization. Model ID4-35B

Forming speed 35S Productivity 16800pcs/day Power 15.2KW Machine

Accessories Spring/Screw/Casters Dimension 1200*1280*1950mm Weight

1680KGS Production size(mm)

400*200*200/400*150*200/400*100*200/240*115*53 The ability to

customize various types of bricksDetailed PhotosFEATURE:1. small

production capacity and small size machine with a reasonable

price2. Low investment high profit3. Wide production range:

concrete hollow block, cement solid block, wall block, interlocking

block, paving brick, color street brick, curbstone.4. Diesel block

machine, it no need electric power, so it could be used in the

village5. It is a hydraulic block machine, so it could produce

stronger and quality bricksWe have a motor type and diesel engine

type hollow brick-making machine. You can choose according to your

requirement.1. Motor type hollow brick-making machine( Inclined

push type and Straight push type)2. Diesel engine type hollow

brick-making machine with small capacity3. Motor-type hollow

brick-making machine with a big capacity4. Diesel engine type

hollow brick-making machine with big capacityCement, sand, clay,

shale and fly ash, lime and construction waste can be used as raw

materials, it can produce different shapes and sizes of bricks by

changing the different molds. this equipment adopts a hydraulic

power system, with stable performance, long service life, and so

on. products with high density, frost resistance, penetration

resistance, sound insulation, heat insulation, and good resistance

to penetration. the shape of the brick produced is of high accuracy

and good flatness is a more ideal environmental protection building

materials equipment.Packaging & Shipping1 unit was packed into an

iron frame and then packed with 5 layers of corrugated carton. 4

strips reinforced the carton. the fix package guaranteed the

machines were not damaged during transportation FAQQ1. What

can we do if there are problems with the products?A: Our engineers

will analyze the problem for you and find the bestsolution. If

problems happened within the guaranteed time, we can replace the

components for you free of charge. We have dealers in some

countries, for some technical problems which you can not solve by

yourself.Q2. What is the delivery time for your products? A: Once

we promise the delivery time, we will try our best to fulfill it.

Special procedures such as emergency inventory will be used to

maintain your uninterrupted supply of the products.Q3. Is there any

guarantee for your productsA: Most of our products have one year

guarantee(for the main parts).Q4. How can you control your product

quality? A: Quality is always considered the most important part of

our manufacturing process. All of our products come under a strict

quality control system from raw material inspection, component

inspecting,semi-finished product inspecting, and performance test

of finished products, to random inspection before delivery. /*

March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Hydraulic Static Pressure Paver Interlocking Building Clay Soil Automatic Cement Fly Ash Sand Concrete Block Hollow Brick Making Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup