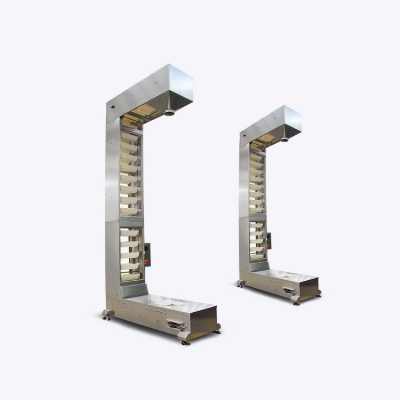

Production DescriptionThe stainless steel Z-type elevator, also

known as the Z-type rotating bucket elevator, Z-type feeding

machine, and Z-type conveyor, is a closed shell that transports

materials through a hopper suspended on a chain, and can be

combined horizontally, vertically, and horizontally. It has the

advantages of large conveying capacity, high lifting height, stable

and reliable operation, and long service life. This elevator can

achieve multi-point discharge or multi-point feeding, reducing the

rate of material damage, and is suitable for conveying small,

granular, and powder non viscous materials.StructuresThe machine

casing adopts a segmented combination, with optional horizontal

length and lifting height. Flexible layout with minimal footprint;

Save factory space and reduce pit depth; The machine operates

safely and reliably, steadily without noise, without scattering,

leaking or flying dust, and is easy to disassemble and repair. It

is an ideal new type of material conveying equipment.Technical

ParametersModelParametersRXZD-3RXZD-6RXZD-10RXZD-15RXZD-20RXZD-25RXZD-30RXZD-35Conveying

capacity100%m³/h61522304556688075%L4.51116.522.533.5425160Silovolumemm36101520253035Widthmm370470870500560690815940Distancemm228.6330Chainchain

pitchmm38.166Chain Qty-2Single chain breaking

load(min)KN37.690sprocketTooth number-2622Pitch

Diametermm316.09463.76Hopper running

speedm/s≤0.3≤0.25Max lifting heightm≤45Max horizontal

conveying distance ≤100Total

Powerkw0.75-221.1-222.2-225.5-225.5-30Optional configurationZ-type

rotary bucket elevator, optional configuration:Case material:

carbon steel, 304 stainless steel, spray molded, 316 stainless

steelHopper material: carbon steel, 304 stainless steel, spray

molded, 316 stainless steelChain material: alloy steel, 304

stainless steel, 316 stainless steelSprocket material: 45 # steel

quenched, 304 stainless steel, 316 stainless steelMotor type:

energy-saving motor, variable frequency motor, explosion-proof

motorControl mode: manual, PLC automaticProduct features:Space

saving and flexible layoutIntegrating horizontal conveying and

vertical lifting, it has a compact structure and a small footprint,

reducing the number of pits.Wide range of improvementThere are few

requirements for the types and characteristics of materials, and

powder, granular, and small pieces of materials can be used.Safe

and reliable operation with low noiseThe trouble-free operation

time exceeds 20000 hours, and the safety configuration is

complete.Customized by usersAccording to the customer's on-site

design, horizontal ≤ 100 meters and vertical ≤ 60 meters can be

used.Application:Currently, it operates normally in the following

automated production industries: pet food industry, puffed food

industry, feed industry, candy industry, dried and fresh fruit

industry, health food industry, grain precision processing

industry, chemical medicine industry, hardware and electrical

materials industry, manufacturing industry, and so on.Food

industry: biscuits, gum, cotton candy, small Mantou, pancakes,

chicken essence, milk tea, jelly, pearl fruit, milk tea powder,

shrimp strips, potato chips, Rice noodles, rice dumpling,

dumplings, chocolate, peanuts, coffee, granulated sugar, nuts,

sugar beans, melon seeds, pistachios, walnuts, almonds, rice,

millet, etcChemical industry: plastic particles (PP, PE, PS),

activated carbon, preservatives, additives, fertilizers,

etcHardware industry: screws, nuts, metal accessories, etcCustomer

Reference /* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Stainless Steel Z&C Type Beans Bucket Conveyor Elevator

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup