CZ INTERCHANGEABLE Roll Forming Machine Roofing Sheet

Tile Roll Forming Machine is one of most popular metal building

material making machines,it can produce many kinds of trapezoidal

tile/panels,like Ag panel or PBR/R panel,which can be widely used

in many scenes,like school,gym, warehouse,etc.1. Component line1000

Roof Panel Cold Roll Forming MachineNo.NameUnitQty1Man-made

uncoilerset12Main machine for roll formingset13Control

systemset14Hydraulic systemset15mold pressing

machine set16Bladeset17 Receiving tableset1Product

parameter SeriesDetailsParameterProducTRaw materialPPGI

/PPGLMaterial thickness0.25-0.8mmProduct cutting

lengthAdjustableCoil ID508 mmCoil width1250 mmCoil

weight5TDecoilerWork typehand typeStructureSteel channel for basic

frameLoading capacity5 TonsCoil inner diameter550-610

mm(adjustable)Max coil width1250 mmRollforming machineFeeding

devicePlatform, the width is adjustableRoller stations16 stagesThe

distance between 2 stages is 443mmRoller shaftShaft

material: 45# steelShaft diameter: φ70 mmRollerRoller

material: 45# steelRoller spacerAnti rusty treatmentWork

speed25m/minMain structureMiddle plate weld with structureMotor

power5.5KW ,SHANGHAI LICHAO BRAND Transmission1.0INCH

CHAINSMachine basic frame400# H steel welded with diagonal

bracing insideBearing Chinese famous brand:

HarbinPLCcontrolsystemFrequency brandDelta (original)PLC brand

PLCDelta (original)Screen typeTouch screen also have buttonScreen

languageEnglish / Chinese/Arabic Low voltage

apparatusTAIWAN DELTA EncoderOmron FunctionCutting to

length, quantity and work speed control.HydraulicsystemWork

typeHydraulic cuttingDriving type By pillar type

cylinderHydraulic motor

power4.0KW Cutter

material Cr12Cutting length

tolerance±1-3mmProductcollecttableLength3mWidth1.3mStructureShaped

steel weldedMachine weightAround 4TonsDetailed

photo Decoiler ( Selectable configuration ):Optional

configuration ): Hydraulic decoiler; Loading Lecel:

5tons(common), 8tons, 10tons, 15tons or as requirement;Loading

Width: Max. 1250mm or 1450mm (common);Loading Inner Diameter:

φ450-550mm;Loading Outer Diameter: Max. φ1500mmForming station

:With feeding material guide, body frame made from H450 type steel

by weldingSide wall thickness: Q235 t30mm ;Tie rod:ф22

GalvanizedRollers manufactured from Gcr15/Cr12 steel,CNC

lathes,Heat Treatment,hard Chrome Coatedwith thickness

0.04mm,surface with mirror treatmentThe warranty for the rollers is

2 yearsShafts Diameter=ф90 mm,precision machinedGear/Sprocket

driving,about 21-step to form(19-step to form and 3 step for

final shaping).Main Motor=18.5KW , Frequency speed

controlSpeed redcucer motor:K series;Size changing motor:6pcs,

Automatically controlled by PLC Programing.Sliding

block:150*150mm;All the screw bolts with grade 8.8Real forming

speed 20m/min (depending on the number of punching holes)With

squareness roller setupPost Hydraulic Cutting Device Post

to cut, stop to cutting,Three pieces type of cutting blade design,

no blanking Hydraulic motor:5.5 KW ;Cutting tool material:

Cr12MoVThe cutting power is provided by the main engine hydraulic

station PLC Controller & Hydraulic SystemCollect

Product Table 1. Automatic Stacker (optional

configuration)--Length: According to

customized;2. Manual Simple collecting product

table (standard configuration)--Length: 3m(common) or as

customized.Product feature 1 More efficient and accurate

execution of production orders;2. High equipment reliability;3.

Little waste of materials and energy;4. High productivity;5. High

quality materials, get a longer service life;6. All parts of

the machine are processed with precision, and the surface of the

roll is chromeplated to ensure that customers can get qualified

products at the same time, it can avoid the scratch of the color

steel surface paint, and increase the service life of the roll;7.

Customized coil processing solutions to solve all aspects of

technical problems.1 More efficient and accurate execution of

production orders;2. High equipment reliability;3. Little waste of

materials and energy;4. High productivity;5. High quality

materials, get a longer service life;6. All parts of the

machine are processed with precision, and the surface of the roll

is chromeplated to ensure that customers can get qualified products

at the same time, it can avoid the scratch of the color steel

surface paint, and increase the service life of the roll;7.

Customized coil processing solutions to solve all aspects of

technical Why Choose this machine? 1. Lifetime seivices2.

Introduced Mitsubishi PLC with touch screen to machine controll

system.3. One worker operation (minimum) 4.

Lifetime>10years: roller cover with 0.05mm chrome72mm diameter

solid steel shaftCutting blade with heat treatment. 5. Cr12

mould steel cutter with quenched treatment. 6. Product

cut-to-length.8.Technician overseas installing and training

availableAfter Sales Service1. Engineer will give free training

lessons to labors in buyer's factory. 2. The Buyer need

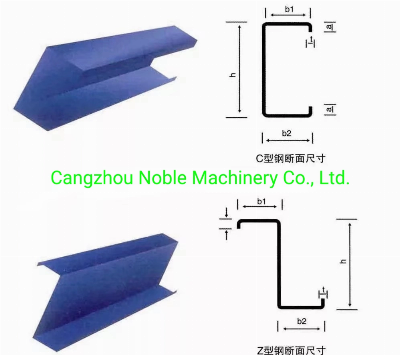

Related products about C and Z Purlin Roll Forming Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup