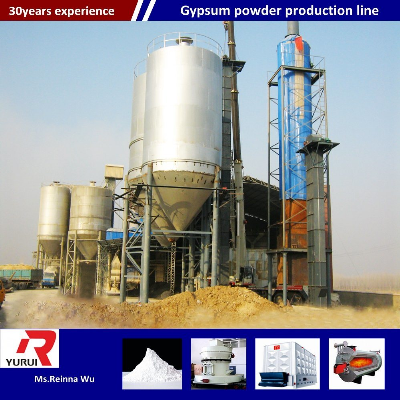

gypsum powder making machine

linephospho gypsum powder production line/china

factory naturalgypsum powder production lineRaw

material requestMain quality indexes of raw materialsCaSO4·2H2O

content:75% ~ 95%Surface water content ≤ 18%Crystal water

content 18-20%Capacity15,000ton-400,000ton/year , based on

24hour/day ,300days/year Fuel Gas /coal /heavy

oil/dieselElectricity 380V/50HZ Quality standardQuality

meets and exceeds the national standard of gypsum powder

Construction gypsum national standard number GB 9776-88

Powder parameters1.Product qualityReach or exceed the china

(GB9776-88building gypsum) requirements.2.Fineness100

mesh-120mesh3.Bending strength Bending strength 1.8 Mpa;

Compressive strength: was 3.0 Mpa.(The bending strength have direct

relations with raw material) 4.Main relative

composition1)Soluble anhydrous gypsum content:≥ 80% adjustable2)The

content of dihydrate gypsum: < 5% adjustable3)Initial setting

time: 3 ~ 8 min adjustable; Final setting time: 6 ~ 15 min

adjustable.4)Scale thick: 78 ~ 85% adjustable.Labor

requirementsFrom raw materials to drying 1 person /8

hoursHeating supply 1 person /8 hoursCalcinate control

1 person /8 hoursElectrical work 1

person /12 hoursMachine repair 1 person /12 hoursUnique

advantage 1.Hammer dryerFunction :The air dryer is used to

bake the gypsum powder water containing less than 5% before

entering the boiling furnace. this step can increase the gypsum

liquidity .when it come to the boiling furnace ,it can easy to

calcinate ,so we have this step 2.Modification

grinding(ball mill )Function :Because the chemical gypsum

powder has the quality problem, through the modification grinding,

changes the chemical gypsum component characteristic, make the

quality similar to the natural gypsum powder. 3.FD - chamber

boiling furnace technology(hot iar )The technology of FD - chamber

boiling furnace technology can effectively prevent the mixing of

raw materials with gypsum powder in the process of calcining

.Traditional calcining technologies such as vertical boiling

furnace , rotary kiln ,general boiling furnace, etc.Due to the

effect of mixing function of the machinery and air flow, dihydrate

gypsum ,semi-hydratedgypsum and anhydrite gypsum three-phase

blending mutually in the process of boiling dehydration,It is

inevitable that the phase composition of the final product will be

polyphasic, and the product quality index will be reduced

significantly.And FD - chamber fluid bed calcining process changes

according to the temperature curve of gypsum powder , artificially

divide calcining process into four relatively independent

dehydration space, effectively avoid the phenomenon of high and low

temperature material blending and the composition of the final

product was improved .In the 1 and 2 areas of the main calcining

furnace, high temperature heat transfer technology is adopted to

rapidly heat and dehydrate the materials that have just entered the

FD- chamber boiling furnace, and slowly dehydrate in the 3 and 4

areas.Under the action of high pressure wind, the whole material

presents a fluid boiling state, which improves the efficiency of

heat transfer and mass transfer in gas and solid powder..

Hot air boiling furnace and hot oil furnace technology

comparison1.Reduce investmentThe system does not use hot oil kiln ,

which saves the fixed investment in this part (e.g., oil furnace

body, circulating oil pump, pipe, insulation, valve, high-low oil

tank, etc.) 2.PowersavingThis system saves the circulation

pump, the base power is 45KW/200T/24 hours, the motor 24 hours

consumption of electricity is 45X24=1080 degrees

3.Maintenance costThe oil stove is need to change a cycle oil once

a year, and the replacement cost is about USD3174.60-4761.9The oil

pipeline should be cleaned regularly, while the boiling wok is

direct heat transfer and does not need to be cleaned.

4.Comprehensive utilization rateBecause of this system, using the

waste heat utilization, tail smoke emission temperature less than

90 ºC, reduces the cost of coal, and heat conduction oil smoke

exhaust temperature is 250 ºC or higher, so the new technology is

more energy saving. Built-in dust collecting device, simple

structure, no need of power, no need maintenance, recovery of

gypsum powder back to the calcining chamber. 2-5 tons of gypsum

powder can be received daily, and 2 to 3 yuan($0.32-$0.48) per ton

of gypsum powder can be reduced. 5.Quality adjustableThe system

adopt FD - chamber boiling furnace technology, gypsum powder under

different air temperature, different area, fully dehydration in

different stages, make the product in the case of without adding

any additives, the setting time can be adjusted in 3-15 minutes and

normal consistency of 66% - 75%. 6.The installation period

is short and the area is smallThis system has simple structure,

compact, no cumbersome pipe valves and related certificates. Easy

maintenance, less land occupy . 7.Environmentally

friendlyThis system

Related products about 30, 000-400, 000 Tons Capacity Gypsum Powder Making Machine for Building Materials/Plaster of Paris Making Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup