Best Selling Fully Automatic Metal Coils Stainless Steel Slitting

Line

Product descriptionRaintech slitting line is mainly

used for slitting and cutting coil materials such as tinplate,

galvanized iron, silicon steel sheet, cold rolled steel strip,

stainless steel strip, aluminum strip, and steel strip. It cuts

metal coils into strips of various widths, and then harvests the

strips into small coils for use in the next process. It is a

necessary equipment for precision cutting of metal strips in the

transformer, motor industry and other metal strips.According to the

thickness of the slitting plate, it is divided into thin plate

slitting line and thick plate slitting line.Work

processePreparation → feeding → unwinding → reclaiming → pinch

feeding → pre-calibration 5 rolls → hydraulic shear → feeding

roller table → deviation correction → slitting → edge wire winding

→ looper bridge → separation shaft → tension table → tension 5 Roll

→ feeding → rewinding → unloading carProcessing material

parametersRaw material: hot rolled steel plate (σs≤410MPa,

σb≤540MPa)Coil thickness: 1.0mm~6.0mm (Q235B)

1.0mm~5.0mm (Q355B)Coil width: 800mm~2000mmInner diameter of coil:

Φ508mm, Φ610mm, Φ760mmCoil outer diameter: Φ1000mm~Φ2000mmCoil

weight: Max.35000KgMAIN TECHNICAL PARAMETERSSlitting line for thin

materialModelParameterMaterialThicknes(mm)Max.Coil

Width(mm)Slitting Strip Width (mm)Slitting

Speed(m/min.)UncoilingWeight(Tons)SSL-1*13000.15-1500-13002450-15010SSL-2*13000.3-2500-130012-3050-20015SSL-2*16000.3-2500-160012-3050-20015SSL-3*16000.3-3500-16008-3050-18020SSL-3*18500.3-3900-18508-3050-18020SSL-4*16001-4900-16006-3050-15025SSL-4*18501-4900-18506-3050-15025Mini

slitting

lineSSSL-1*3500.1-180-3506-3050-1003SSSL-2*3500.2-280-3506-3050-2003SSSL-2*4500.2-280-4506-3050-2005SSSL-2*6500.2-280-6506-3050-1807Slitting

line for thick materialModelParameterMaterialThicknes(mm)Max.Coil

Width(mm)Slitting Strip NumberSlitting

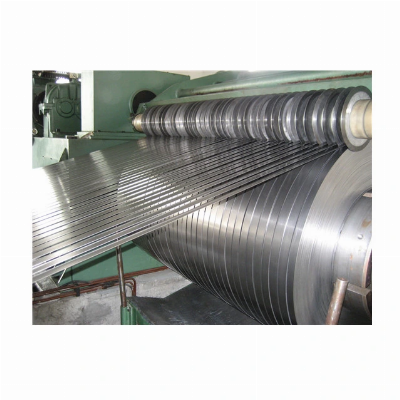

Speed(m/min.)UncoilingWeight(Tons)SSL-6*16001-6900-16006-3030-10025SSL-6*18501-6900-18506-3030-10030SSL-6*20001-6900-20006-3030-10030SSL-8*16001-8900-16006-3030-8025SSL-8*18501-8900-18506-3030-8025SSL-8*20001-8900-20006-3030-8025SSL-12*16002-12900-16005-3020-5030SSL-12*20002-12900-20005-3020-5030SSL-16*20004-16900-20005-3010-3030Workpiece

PictureOur AdvantagesTechnical Strength1.We adopts individual

archway stands for rollers station, more strong and rigidity

structure than other suppliers in china.2. Our engineer always keep

on design advanced , humane and most economic resolution for our

customers, considering customers long time machine life, low cost

maintenance and easy operation, save the cost of labor,

maintenance, training for users. At same time, much higher

efficiencyMachine Advantage1. We have an experienced expert with

young active technical team, which can provide the professional

with improved design solutions for our customers , assure that can

satisfy various customer's special requirement by cost-effective

way.2.Individual gearbox for each archway rollers set, to assure

the precision of the profile.3.All of the machine main body and

parts are quenched, with higher hardness(HRC58-62) and

wear resistance, while other suppliers only rough steel

welded.4.The rollers material is American D2 and D3 standards,

with long service life and low maintenance cost.5.Professional

Germany roller design software-Copra.6.Long machine life, all

of our machines can be used stable performance for more than

10-15 year, while other small and low quality supplier's machine

only can be used for 1-2 years.Packaging & Shipping1 Lifting

the machine into container2 Loading the packages to

container3 Fix with steel wire ropes in container to avoid

damage4 Close and sealthe container5 Transport container

to the port6 Ships and our machines go to the destination

portFAQ1. Q: Are you a Manufacturer or a trading company?

A:We are a professional manufacturer with more than 15

experience in manufacturing, assembling and selling in this field.

We have our own factories as well as trading companies2. Q: How

long have your factory been in this field? And how many staff do

you have? A: We have been in this field mode than 12

years since the year of 2008, total staff more than 100.3. Q:Where

are you and how can I visit you? A: Our factory

located in Jinan City, Shandong Province China, contact us before

your visit in order that we can arrange the good reception.4.

Q: Can you provide a customized solutions? A:

Yes, our engineers are pleased to listen your idea and customized

design is available5. Q: What about the warranty?

A: We provide 12 months warranty since the machine arrival.

free charge of spare parts and regularly maintenance service.6.

Q:How about the delivery time ? A: The delivery

time is different on different products.We never receive any

complain from our customers for the delivery time7. Q: What about

the package and shipment , worry about da

Related products about Best Selling Fully Automatic Metal Coils Stainless Steel Slitting Line

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup