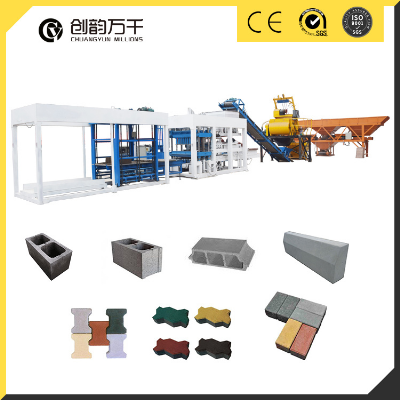

Full Automatic Hydraulic Cement Brick Making Block Equipment

(QT10-15) Introduction: QT10-15 Block making machine is one of

our hot sale block making machine which can produce all types of

hollow blocks, solid block, paver, curbstone and so on. In order to

suit the overseas markets and ensure the machine work high

efficiency, we are constantly updating and improving the quality

and technology., QT10-15 automatic block making

machine main dataDimension of host machine3500×2220×2850mmcontrol

stylePLCforming styleHydraulicVibration force100KNvibrator

styletable and mould vibrate togatherraw material feeding style360

degree revoleforming hight40-250mmmoulding period15-20Smoulding

aera1025×810mmsize of pallet1350×900×30mmweight of host

machine14tonMixer styleJS750General water

Consumption12T/dayVoltage220/240/380/440V Simple block machine

line area neededWorkshop200m2Office100m2Total areaAbout

2000m2 block making machineoperate1Material loader1Drive

forklift1Feeding pallets1Maintain1Total5the machine advantages are

as shown following. 1. 4 vibration motors: Our vibration

system adopts 4 vibration motors,vertical vibration onto 4 corners

of the platform,vibration evenly strong and quickly,molding

fast,reduce the friction with the mold,extend the service life of

the mold. 2. Lengthened vibration shaft and vibation

box: We adopt lengthened vibration shaft and vibation box to

make the vibration platform vibrate stably with more strong and

less noise.Our vibration box is cast,won't leak oil. 3.Siemens PLC

and vibration motors: Adopts Siemens PLC and

vibration motors to make sure our machine work more efficiently and

stably. 4. Japan YUKEN hydraulic component: hydraulic system adopts

the YUKEN proportional valve and multi direction communication

control system,which can adjust any actio in al direction to make

our machine working more stable and sensitive. 5.Block mould:Use

manganse steel material,with the liner cutting and heat treatment

technology,extend 50%service life. 6.Material Feeder: Adopt

German technology wich uses a swinging spline shaft,makes the raw

material evenly into the mold,reducing ther error of the brick,and

this system has a low falure rate

Theoretical production capacityNoSize(LxWxH)Reference picPcs/MouldPcs/HourPcs/Shift1400x200x200mm 81440-168011520-134402400x100x200mm162880-336023040-268803400x150x200mm101800-210014400-168004400x250x200mm81080-12608640-100805230x110x70mmSolid

brick458100-1080064800-864006200x100x60 275760460807200x163x60 18360028800

Our service1. In the process of equipment production, we check

the quality of equipment production at any time, carry

out ex-factory testing before shipment to ensure product

quality. 2. Send our engineers to guide customers in

installation and commissioning. 3. Free supply of spare parts and

tools that enough1 for one year. 4. The warranty period

is one year. For any quality problems during the warranty period,

our company will repair or replace spare parts free of charge.

5. Our company has been worked for 25 years. We can be found

at any time. /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Latest Products in Market Qt 10-15 Baking Free Brick Making Machine Paver Block Making Machine for Sale

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup