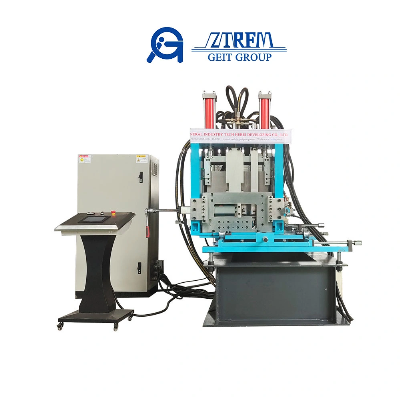

Product DescriptionSteel Profile C Z Exchange Purlin Roll Forming

MachineSteel Profile C Z purlin is widely used in purlin and metal

steel structure building and wall beam.Also can be assembled into

the lightweight roof truss,bracket and other architectural

components.In addition, it can also be used in light industria

manufacturing of machinery, such as columns, beams.Product

ParametersNo.ItemUnitParameterRemark1MaterialType GI,GL,G550,Aluminum Thickness

of Materialmm1.5-3.0mmCommon Thickness; Adjustable As Customer

Requirement2Material WidthmmAs Required Coil

Weighttons5T 3Production

Speedm/min0-15m/min(common)Adjustable; Or High

Speed4ProductmmC80-C300As Customized5Roller

Material Cr15According to designRoller Stations 16-18

StationsAccording to design6Driving Type By Chain or Gear or

Gearbox7Motor PowerkW18.5kWAccording to design8Brand of Electric

Control

System Delta 9Dimension(L*W*H)m9600*1200*800mmAccording

to design10WarrantyMonth15 months Detailed

PhotosProcess Flow:Uncoiler--Feeding and Leveling Device--Punching

Device--Roll Forming Machine--Hydraulic Cutter--Collecting Product

TableDecoiler1. Loading Capacity: 5T2. Coil Width: Max. 800mm3.

Coil Inner Diameter: 450-550mm4. Structure: Welded by The Steel

Plates and Profiled Bar.5. Size: ~1800×1600×1500mm(L×W×H)6.

Feature: 6.1.The Shrink and Expand of The Core is Manually,

with Manual Brake;6.2.The Coil Moving Forward or Recerse is Pulled

Passively by Roll Forming Machine.7. Founction: It is used to

support the steel coil and uncoil it in a turnable way.Feeding and

Leveling Device1. Feeding Type:Adjustable2. Feeding Width Range:

170-550mm3. Entrance and Guide Roller: Diameter φ65mm,4. Leveling

Roller: Upper 3 Rollers, Down 4 Rollers(Total 7 Rollers);5.

Leveling Roller Diameter: φ76mm6. Driving Motor: 4kW AC Motor;7.

Feature: Adjustable Center of The Forming Rollers and of Sufficient

Length to Prevent Laternal Movement of The Strip on its Entry to

Leveling Device. And The Material of Rollers Could Stop Scratching

The Zinc of The Steel.Main Roll Forming Machine 1. Machine

frame:350mm H beam structure , 300H supporter2. Roller quantity:18

sets, size adjustment is controlled by electric buttons.3. Roller

Material:Main rollers:GCr15 Supporting side

rollers:Cr12 Roller4. Shafts Material:Motor drive shaft: 40Cr

steel Other roll shaft: 45# steel6. Forming

speed: 0-30 m/min7. Transmission way: By chainHydraulic

Cutter 1. Main Power: 5 kW2. Cutting Blade: Cr12MoV3. Cutting

Tolerance: ±1.5mm/12m4. Cutting Type: The Unbridled Shearing

System, You can Cut All Size Products by Adjusting the Blade, It is

much Easier than Traditional Shearing System.5. Feature: PLC

Automatic Size Adjustment, You Can Adjust the Rollers by Using

Buttons on the PLC Cabinet Screen, It can Save A Lot Labor and

Time.PLC Control Cabinet1. Main Accessories Origin: 1.1 PLC:

Delta/Panasonic/Siemens1.2 Touch Screen: Delta or Others1.4 Length

Encoder: Japan Omron1.5 Languages: Chinese + English (+As

Customized)2. All of These Parts are World Fomous Brands, Accurate

and Durable, and If it doesn't work, You can Buy Parts very

easy.Hydraulic Oil Pump Station1. Hydraulic Motor: 5.5 kW2. Oil:

46#Collecting Product Table 1. Length: 3m2. Structure: The

Frame Body is Welded with Angle Steel and Angle Steel, and the

Surface is Loaded with Rollers.3. Feature: It is Simple and

Welcomed by Many Customers, Low Cost and Portable.Product Features1

More efficient and accurate execution of production orders;2. High

equipment reliability;3. Little waste of materials and energy;4.

High productivity;5. High quality materials, get a longer

service life;6. All parts of the machine are processed with

precision, and the surface of the roll is chromeplated to ensure

that customers can get qualified products at the same time, it can

avoid the scratch of the color steel surface paint, and increase

the service life of the roll;7. Customized coil processing

solutions to solve all aspects of technical problems.Company

ProfileGeneral Industry tech Hebei Developing Co., Ltd

(GEIT) is aimed at providing our customers with the best

quality metal rolling automation solutions and after-sale

s service. At present, our company has more than 10 years

of designing and making the cold roll forming machine, and our

products have been sold to more than 60 countries and areas,

achieving good fame. GEIT are capacable of and confident with our

product that will make its name in China and will be famous in the

world.Backed with the powerful technology and the perfect market

service system, and holding the idea of globalization, we have

expanded our international market step by step. Opportunities

accompanying with challenges, and we are always full of

confidence.Why Choose Us1. Equipment research and

developing Our company commits to provide customized coil

processing solution according to each customer's specific

metalworking process. With experienced technical technical team and

continuous researching investment, we are capa

Related products about PLC CE Approved Ztrfm Structure Purlin Making C Purling Machine Roll Forming Manufacture

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup