Product Description

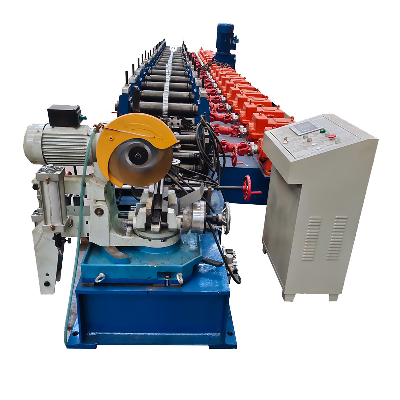

Solar Panel Strut Channel Machinery ManufacturerStrut

channel roll forming machine is also called like seismic

support roll forming machine or seismic channel roll

forming machine, its product is used to mount, brace, support, and

connect lightweight structural loads in building construction. Our

strut channel roll forming machine is suitable to

produce strut channels with 12 gauge(2.6mm) or 14

gauge(1.9mm) thick sheet metal (normally range 2-2.5mm),

raw material could be Hot-rolled and cold rolled steel, Hot-dip

galvanized sheet, Pre-Galvanized Steel, Mill(Plain/Black) Steel,

Aluminum, Stainless Steel etc. And according to slot type, our

machine could produce solid channel, slotted channel, half slotted

channel, long slotted channel, punched channel, punched and slotted

channel etc.KEFA has many experience at solar

photovoltaic stents roll forming machine. We exported to Saudi

Arabia, Turkey, Iraq, India, Kuwait, Qatar, Pakistan, Argentina

etc. We have made the strut channel profile, and American standard

profile as well. The most popular size of strut channel profile is

40*21, 41*41, 41*62, and our roll forming machine could produce 3-5

sizes(eg: 41x21, 41x41, 41x62) in one machine (by manually change

spacers), the working speed can reach 16m/min.Now we have two

workshops producing solar photovoltaic stents to export.

If you come to visit us, we would like to show you the producing

line. We make different solutions according to

customers' drawing, tolerance and budget, offering

professional one-to-one service, adaptable for your every need.

Whichever line you choose, the quality of KEFA Machinery will

ensure you obtain perfectly functional

profiles.Description:This solar photovoltaic stents roll

forming production line is very efficient and higher yield. In

this case, we produce 5 different sizes totally and production

speed is up to 16m/min. Besides, we recommend burr-free saw cutting

to reduce steel wastage and manufacturing cost, reasonable range of

burr improves the quality of profile and price, bringing greater

benefits to customers. We also adopts the flying saw cutting system

to optimize production. This is the best configuration of solar

photovoltaic stents roll forming machine.Flow Chart:Hydraulic

decoiler-Levler-servo feeder-Press- Roll former-Flying saw cut-Out

tableProduct Parameters Automatic Roll Forming

MachineMachinable Material :A) Galvanized

SteelThickness(MM): 2-3mmB) PPGIC) Carbon steelYield strength

:250 - 550 MpaTensil stress :G250 Mpa-G550 MpaDecoiler :Manual

decoiler* Hydraulic decoiler (Optional)Punching system :Hydraulic

punching station* Punching press (Optional)Forming station

:According to your profile drawingsMain machine motor brand

:Shanghai Dedong (Sino-Germany Brand)* Siemens (Optional)Driving

system :Chain drive or Gear drive* Gearbox drive (Optional)Machine

structure:Cantilever type* Forged Iron station (Optional)Forming

speed :10-20 (M/MIN)* Or according to your profile drawingsRollers'

material :GCr 15* SKD-11 (Optional)Cutting system :Post-cutting*

Pre-cutting (Optional)Frequency changer brand :Yaskawa* Siemens

(Optional)PLC brand :Panasonic* Siemens (Optional)Power supply

:380V 50Hz 3ph* Or according to your requirmentMachine color

:Industrial blue* Or according to your requirmentDetailed

PhotosCompany Profile Certifications Packaging &

Shipping FAQ1.How to maintain the machine?Answer: add

mechanical lubrication equipment to chain, bearing and cutting

slide every month. Add mechanical lubrication to the case every

half a year.2. Do you sell only standard machines?A: No, most of

our machines are built according to customers specifications, using

top brand name components.3.How many workers to operate the

machine?A:Only 1-2 workers.4. How to visit your company?a.Fly to

Beijing airport: By high speed train From Beijing Nan Station to

Cangzhou West Station(1 hour), then we can pick you up .b.Fly to

Shanghai Airport: By high speed train From Shanghai Hongqiao to

Cangzhou West station(4.5 hours), then we can pick you up.5. What

can you do if the machine broken?Our machine's warranty period is

12months,if the broken parts can't be repaired,we can send the new

parts to replace the broken parts for free,but you need pay the

express cost yourself.if over warranty period,we can for to solve

the problems via negotiation,and we supply the technical support

for the whole life of the equipment.6.How can I trust you that

machines pasted testing running before shipping?A: 1) We record the

testing video for your reference. Or,2) Please visit company and

test machine if convenient./* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Solar Panel Strut Channel Machinery Manufacturer

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup