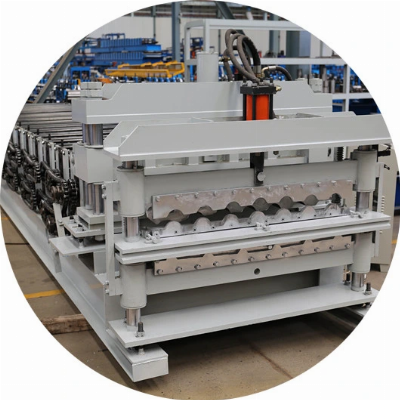

2 In 1 Double Layer Roll Forming Machine For Metcoppo And Long Span

Roof Sheetspecialized manfacturer of roll forming machine,different

designs can be customized as your request.Different length can be

done,with PLC and speed controller.different roof sheet designs can

be custmozied as customer request:metal roof tilesstanding seam

roofscorrugated metal roofingibr roof sheettr4 sheetsclip lock

panelppgi roofsaluzinc roof panel product description Metal

Roofing Panel Roll Forming Machine-Roof Sheet Forming

Machine Name Glazed tile IBR roofing sheet Double layer

roof tile making roll forming machine Suitable

Material PPGI, PI, CR, Q235 Or Equivalent Control

System Auto Control Operation Panel 7 Inch Touch

Screen Warranty 18 Months Life Time At Least 15

Years Color Blue Or At Buyer's

Requirement Certification CE,

ISO Noice Environment-friendly, Low

Noise After-sales Service Provided Engineers Available To

Service Machinery Overseas 1.Photoes Of roll forming

MachineGlazed tile IBR roofing sheet Double layer roof tile making

roll forming machineMore Details of our machineColored Glazed tile

IBR roofing sheet Double layer roof tile making roll forming

machine 2. Technical Parameters:Metal Roofing Panel Roll

Forming Machine-Roof Sheet Forming Machine A. GeneralGlazed

tile IBR roofing sheet Double layer roof tile making roll forming

machine Suitable Material HRB60 or equivalent Material Thickness 0.2-0.6 mm Length of the Sheet You can set the length according to your need. It is controlled by PLC which can ensure the accuracy of ±1mm. Cutting Automatically stop and cutting when it comes to the set length.B.

Components DetailsGlazed tile IBR roofing sheet Double layer roof

tile making roll forming

machine Roller Material High grade 45#

steel. Hard chrome plating, 0.05mm. Main Frame 350# steel. More stable and no shaking. Middle Plate 16mm. We use thicker plates to ensure stability

of our products. Forming Steps 11-16, according to the drawing. Shaft Material Φ70 mm, high grade 45# steel. Treating process: tempering- finish turning, high rigidity, hard to deform. Cutting Blade Material Cr12, hardness HRC60-62. Treating process: heat treatment- plane abrasion-wire electrode cutting. c.Component

lineGlazed tile IBR roofing sheet Double layer roof tile making

roll forming machineNONameUnitQty1Man-made decoilerset12Main

machine for roll formingset13Control systemset14Hydraulic

systemset1 3. Working Flow:Glazed tile IBR roofing sheet

Double layer roof tile making roll forming

machine Loading Company Information Packaging & Shipping

Package of Glazed tile IBR roofing sheet Double layer

roof tile making roll forming machine1). Container packing of the

line suitable for overseas shipping2). The subjects can be loaded

in one 20' container.3). Package style: Covered by plastic film,

spare parts and some small parts packed in carton

box. Certifications Our Services

A. One-Years product warranty.B. Training and

installation available.C. The technical support for the whole

life.Contactor Welcome to contact me!Glazed tile IBR roofing sheet

Double layer roof tile making roll forming machine/* March 10, 2023

17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about 2 in 1 Double Layer Roll Forming Machine for Metcoppo and Long Span Roof Sheet

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup