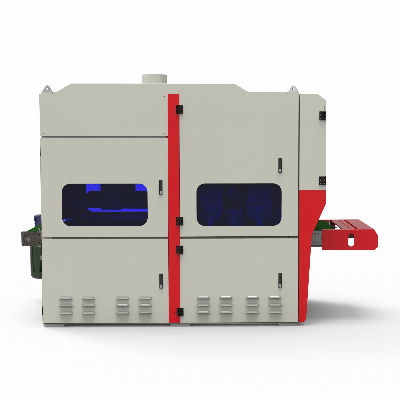

Product DescriptionLaser Cutting Stamping Parts Flat

Sheet Metal Deburring Grinding Polishing Machine ManufacturerThis

equipment is a dry abrasive belt model with double sand racks.

It is mainly used for deburring, workpiece edge, hole deburring

effect, sanding the surface of the workpiece, making the contour

edges around the surface of the workpiece and in the hole smooth

and round, and realizing wire drawing, descaling, polishing, and

slight pouring on the surface of metal sheets. Angle and other

processing. The burrs generated in the processes of stamping,

shearing, laser machine cutting, plasma cutting, etc. can be

removed in all directions at one time. The processing process is

safe and reliable, so that the workpiece can achieve perfect

results.This deburring machine support laser cutting machine, CNC

stamping, various CNC processing or other machining deburring front

production line. It can work for removal of parts surface, contour

edge and hole edge burr and uniform chamfering.Main Technical

Data ModelDouble Wide Belts Sanding

MachineUnitSRR630SpecificationsSand cutting widthmm40-630Sand

cutting thicknessmm3-160The shortest sand cutting lengthmm500Speed

of 1st sanding belt setm/s19Speed of 2nd sanding belt

setm/s16Feeding speedm/min5-27Sanding belt sizemm650*2100Motor

PowerTotal motor powerKW20.741st belt motorKW112nd belt

motorKW7.5Feeding motorKW1.5Dust brush motorKW0.37Workbench lifting

motorkW0.37Pressure & DiameterVacuum port

diametermm5*Φ150Working pressureMPa0.6Dimensions

& WeightOverall

dimensionsmm2120*1280*2050 Weightkg1950 1.

Motors for coarse sanding, semi-fine sanding, fine sanding are

inside setted, to make cleaning appearance.2. The second group of

idler rollers is anti-reversal roller, to protect the safety of the

operator.3. The support plates are made of high quality casting,

which makes our machine more stable and high accuracy.4. Double

pressure roller structure to ensure seady and smooth feeding.5.

SPR-RP series configured with precision spiral planing cutter

module, and in keyboard type sectional pressuring structure. It's

can plan and sanding at the same time, stablly and precisely.6.

SRR630S type is equipped with 8 sets feeding rollers,

3 front, 2 in middle, 3 rear. So it can apply to

materails over 230mm length. Machine

Application Application materials: This series of

Metal deburring machines are suitable for stainless steel, steel,

aluminium, copper, etc.Application products: Removal of burrs

on laser-cut, waterjet-cut and punched productsApplication

Industries: Metal deburring machines are widely used in manufacture

Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters,

Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals

Components and Parts, Ironware, Chassis, Racks & Cabinets

Processing, Metal crafts, metal art ware, elevator panel, hardware,

auto parts, Glasses Frame, Electronic Parts, Nameplates, etcSheet

Metal Deburring Machine Quality Control1. All-round quality control

in the procurement process, all components used famous brands2. All

machines can be traced back to the production batch, which is

convenient for quality control and after-sales.3. Round after round

of testing before delivery to ensure that the machines arrived

without any possibility of problems. Company ProfileJinan

Xingsai Machinery Manufacturing Co.,Ltd is a professional

manufacturer specializing in the development and production of all

kinds of polishing machinery and grinding supplies. With more than

20 years experience in metal surface treatment technology, can be

customized according to customer requirements and polishing machine

and production line, including vibration polishing machine,

centrifugal polishing machine, magnetic polishing machine and

plasma polishing machine, our company has many years experience in

professional design team, we trained team of engineers is equipped

with the latest technology, we can according to customer'sproduct

features, Provide the most suitable solution. Why Choose Our

Company?1,23 Years Experience Professional Manufacturer.2, We have

CE and ISO9001 certification.3, Quickly delivery and Competitive

price with high quality4 , We can design and supply the whole

production line for you. Detailed Photos

Certifications After Sales Service Our

Sercive:1.We have After-sale department,every client can get

a timely feedback when they have any trouble about our

machine.2.We have installation team,if you need,we will provide

installation service.3.Our equipment warranty period is

1 years,within this time,we will provide free maintenance.4.If

you have any other question or demand,please feel free to contact

our businessmen,they will reply you within 8 hours.FAQ

1. Are you a manufacturer or a trader?We are professional

manufacturer of nonwoven machine since 1999, our machine have been

exported to 76 countries globally, which is well known in the

international market.2. Where is your factory?Our factory is

located in sha

Related products about Automatic Flat Polishing Machine Metal Polishing Derusting Machine Stainless Steel Sheet Brushing Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup