Product DescriptionTechnical Parameters Working width

≤1250MMWorking length 350-3000MMWorking thickness

≤150MMWorking Station Height 900±20MMConveying Speed

2-6M/MINPaint Reclaim Belt Width 16501650*8680MMAir

consumption 2m³/MINExhaust Air Volume

10000m³/hConveying Motor Power

1.1KWCleaning Motor Power 1.1KWRear Conveyor Power

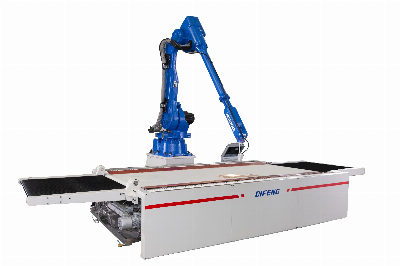

0.37KWExhaust Motor Power 7.5KWHighlightsThe hollow arm six axis

robot has an ultra long reach range, which can achieve

accurate performance and optimize production capacity.Fast

shaft speed and acceleration capabilities shorten cycle time and

improve throughput, while the hollow arm provides excellent cable

protection.Interference reduction design offers close

placement in compact spaces, with simplified upper arm, which

can contact parts in a narrow space.With a wide range of wrist

motion, high torque & penetration ratings,

the ability to install peripherals in multiple locations,

suitable for various tasks.Robot Regulation CabinetConveying and

Paint Reclaim Device Equipped with heavy duty carbon fiber

conveyor covering the width of 1650mm, no paint leakage to the

other side of work piece.Equipped with automatic centering device

of conveyor belt, the operation is stable.The running speed is

controlled and managed by the frequency

converter.Rear conveyorThe rear conveying system adopts a

rollover structure, which can automatically rollover when cleaning

the system, and is equipped with 2 sets of cylinder

drive.Independent dynamic drive and variable frequency speed

regulation are adopted to realize the matching with the speed of

medium conveyor belt.The discharge conveyor belt adopts a special

flange (semicircular) structure to minimize the contact of coated

work pieces and prevent secondary pollution.Paint Reclaim

SystemCounter rotating roller removes and recovers lacquer from

belt conveyor,while the rest of the system ensures the cleaning of

the CFB belt.Cleaning solvent consumption and end-of-shift clean-up

time have been reduced to minimum.It has the smallest closed

solvent chamber, which limits the volatilization of the solvent and

minimizes the consumption of cleaning solvent and the cleaning time

after work.Spraying SystemTechnical ParametersWorking

Pressure≥0.6MpaAir Consumption(Gun)3-7.5m³/hAir

consumption(pump)42m³/hCoating materials temperature ≤50ºCAdvantage

of AVX Spraying Guns The coating has high transfer efficiency

and excellent atomization quality.Modular design, easy

maintenanceThe spraying environment is obviously improved, and the

coating is saved while improving the spraying quality.Advantage of

AVX Spraying1. Air mixing spraying combines the advantages of air

spraying and airless spraying. It uses a special plunger pump

with a certain pressure ratio to pressurize the coating to 4 ~

5MPa, and then spray it after atomization by the nozzle of the

special air mixing spray gun.2. Equipped with medium pressure

plunger pump, the paint supply is stable and the fluctuation is

small, which is suitable for the transportation of medium and high

viscosity paint.3. The air mixing spray gun has excellent

atomization performance, so as to achieve high painting quality and

save paint greatly.4. The paint circulation can realize rapid

cleaning in the base.5. The air mixing spray gun has a large

spraying amount, about 10 times that of the air spray gun;

Therefore, the construction times can be reduced, so the air mixing

spraying has high production efficiency.6. It has good manufacture

ability, wide viscosity adaptability, many types of applicable

coatings, can reduce the amount of thinner, and is easy to operate,

so it is convenient for popularization and application.lThe area is

equipped with a paint mist filtration and purification system to

filter the paint mist in the initial effect.lWork with dust-free

spraying booth to ensure clean environment and stable coating

quality. Control function 1. It meets the requirements

of industrial 4.0 connection communication and can realize

communication with the user's information system; For data

acquisition;2. This series of products are controlled by PLC and

touch screen to realize good man-machine dialogue and automatic

control.3. The system functions are highly integrated to

simplify the operation;Perfect monitoring and protection function

of system service; Scope of applicationIt's suitable for

continuous, high-quality and high-efficiency painting operations of

panel furniture, solid wood doors, cabinet doors, bathroom panels,

handicraft, ceramic tiles, decorative panels, metal panels, glass

panels and other workpieces. Targeted coating solution:According to

different product types, different coating production process

requirements, different types of paint, the integration of

automatic coating machine equipment, providing complete paint

customized solutions, design painting process and painting workshop

process layout. Company Profile Guangdong Shunde Difeng

Machinery Co.,Ltd, was founded in 2010. It is a national

Related products about Robotic Spray Finishing for Irregular Shaped Cabinet Shutters Doors Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup