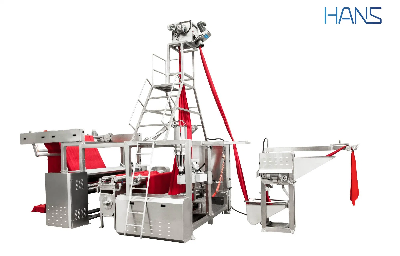

Fabric slitting equipmentFeatures:- The slitting line major used

for slitting and opening of knitted and woven fabrics, both tubular

and open width form fabrics - Automatic rope detwisting made by

stainless steel, mounted on a fixed tubular flatform - High

automation grade with PLC and inverter system - High efficiency

washing tank after slitting basket - Fully automatic grade slitting

basket - Can be used for long pile towel fulffy washing process -

Single padder or double padder for dewatering or chemical

permeation - Automatic rotary filtering devecie - Low tension

washing effect - English version operation system - Complete

finishing line, which place before stenter finishing machine

SpecificationModelHSL-2600Pre squeezer unitWith small J scray

device for fabric storageMax. working

width2400mmSpeed100m/minMachine bodyStainless steel 304Washing

tankSingle tank or double washing tankAutomatic filtering

deviceRotary filteringPadderHigh efficieny padderTouch Screen

ControllerAll production data can be controlled by touch screen

controllerMain Flow Chart:Pre squeezer unit → Rope opener →

Slitting device → Centering unit → Tension sensor → Washing tank →

Padder → Plaiter Machine Layout :Fabric rope opener

machineFeatures: - Suitable for open width knit fabric, woven,

towel fabrics after dyeing process rope opening and detwisting

process- Long life working condition with stainless steel body-

Fully automatic automation system- Speed adjustable- Rotation table

optionSpecification:ModelHSL-2600Max. working width2400mmMaterial

of bodyStainless steel 304Speed5-80m/min

(Adjustable)Voltage380V/50HZAutomationPLC+ InverterOperation

panelEnglish VersionMore Information, Please click

here!https://71d09e065b2be768.en.made-in-china.com/product/swJTdZQjMXpc/China-Fabric-Rope-Opener-Detwister-Machine-for-Knit-Fabric.htmlTubular

Sewing MachineApplication:- After tubular slitting process, fabric

will be open width form, in order to achieve unique dyeing result,

should back sewing the fabric in a tubular form Features: - Touch

screen controlled, fully automatic tubular sewing - Equipped with

fabric inlet tension adjustor device - Automatic stop during

machine running without fabrics - Sewing device: Juki - Edge width

adjustable - Infrared centering device control the centering

process of fabrics, make sure fabric running in the center area of

the machine - This tubular sewing machine is equipped with 3

spinder spreader, make sure good fabric edge opening result before

the sewing device - Speed adjustable Specification:

ModelHTS-2600Working width2400mmVoltage380V/50HZSewing

speed0-40m/minInstalled power5KWMachine weight1600KG More

Information, Please click here!

https://71d09e065b2be768.en.made-in-china.com/product/NZQAqToggSUx/China-Tube-Sewing-Machine-for-After-Slitted-Fabrics.html

/* March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Texile Dyeing Finishing Circular Knitted Woven Fabric Slitting Rope Opening Washing Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup