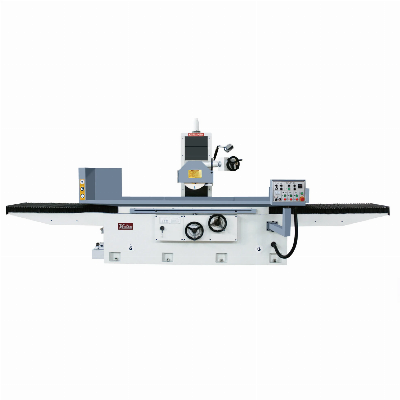

1. Picture AHR: 2-axis automatic feed hydraulic

automatic longitudinal feedelectronic

automatic cross feedelectronic rapid up and down

feed AHD: 3-axis

automatic feed hydraulic

automatic longitudinal feedelectronic

automatic cross feedincremental auto down feed (use hydraulic

system and gear

box) 2. ParametersParametersUnitKGS615AHR KGS615AHDWorking Surface of Tablemm600×1500 (24"×60")600×1500 (24"×60")Max.Table Travelmm16001600Max.Cross Travelmm650650Distance Between Table Surface and Spindle Centermm600600Max.Table Loadkgs800800T-Solt(Number×Width)mm3×163×16Table Speedm/min5~255~25Crossfeed Handwheel1gardmm0.020.021 rev55Automatic Crossfeed of Saddlemm0.5~120.5~12Power Cross Feed50HZmm/min1250125060HZ15001500Grinding Wheel Dimensionsmm355×50×127355×50×127Spindle Speed50HZrpm1450145060HZ17401740Vertical Handwheel1gardmm0.0020.0021 rev0.50.5Automatic Down Feed Ratemm-0.005~0.04Power Head Incrementmm/min230230Spindle Motorkw7.57.5Vertical Motorw370370Hydraulic Motorkw5.55.5Dust Collection Motorw550550Coolant Motorw9090Crossfeed Motorw370370Floor Spacemm5810×24455810×2445Packing Dimensionsmm5800×2260×22505800×2260×2250Net Weightkgs72507250Gross Weightkgs825082503.

Main Configuration of Grinding Machine1. Spindle motor: ABB

brand.2. Spindle bearing: NSK brand P4 grade precision ball bearing

which from Japan.3. Cross screw: P5 grade precision ball screw.4.

Main electrical components: SIEMENS brand.5. Main hydraulic

components: brand from TAIWAN.4. Standard Accessories

1Grinding wheel2Wheel

flange3Wheel balancing base4Wheel balancing arbor5Extractor6Diamond

dresser7Leveling pad8Anchor bolt9Tool box with tools10Electric

magnetic chuck 11Cooling system12Working light

5. Optional

Accessories Serial No.Name of Article1rear splash guard

2DRO (digital

read out)3overhead parallel dresser 4hydraulic tank oil

cooling5cooling & suction device 6magnetic

separator 7cooling

magnetic paper filter Note6 and 7, select one just OK.6.

Feature1. Well designed cast iron structure provides excellent

dampening2. Flange mount spindle cartridge for superior side

grinding rigidity 3. Grinding spindle features

low-maintenance preloaded high precision angular ballbearings(NSK

P4 grade)4. "V" and flat type guide way which precision

hand scrapped turcite saddle ways for smooth and long lasting

performance5. Table guideways are hardened, ground and

counter-laminated with PTFE(TEFLON) to ensure high

wear-resistance6. Centralized automatic lubrication

system ,supplies oil to guide-ways and lead-screws as the

machine operates. This system ensures all the critical components

are lubricated with the right amount of oil at all times7. Separate

hydraulic tank prevents heat and vibrations from being transferred

to the machine8. Electric components and functional modules are

well arranged and packed in the electric cabinet, making

maintenance and trouble-shooting easily accessible9. Magnetic force

can be adjusted10. Safety 24V control circuit power7. Company &

FactoryNantong Kaite Machine Tool Co., Ltd. A Sino-US joint

venture machine tool company with KENT INDUSTRIAL (USA)

INC. KAITE specializes in manufacturing precision surface

grinding and milling machine since 1999.KAITE supply the USA

quality machines and with China price. KAITE is located in

Nantong city, Jiangsu Province where near Shanghai city and welcome

to visit us!8. Delivery Picture /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Kgs615ahr/Ahd-600X1500mm Magnetic Chuck Large Surface Grinding Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup