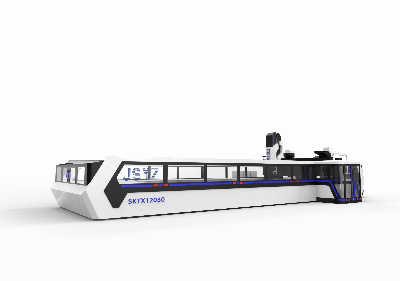

The machine tool adopts the international advanced machine tool

structure, with fixed workbench, gantry frame in the sliding

platform to do front and back (X direction) movement, front

side milling power head along the beam to do left and

right (Y direction) movement, front side milling power head sliding

pillow along the sliding seat to do up and down (Z to)

movement, rear two load milling head along the beam to do the left

and right (Y1, Y2) movement.The gantry beam is located on the left

and right columns, forming a strong gantry frame structure

with high rigidity machining properties.The machine is equipped

with plate chain automatic dust exhaust and collecting car, cooling

device is external windCooling, can timely take away the heat

generated by the process.The sliding pillow is made of high quality

casting parts (HT 300), with good rigidity, high precision and

excellent performanceThe upper and lower movement along the sliding

seat constitutes the Z-axis movement. The guide rail is

a square quenching-stick plastic guide rail pair, high stiffness,

good vibration absorption.The machine bed body, gantry beam,

workbench are all welded structural parts, after the

overall annealing to stress treatment, the accuracy is

stable.1. The main use of the machine tool:This machine tool adopts

the international advanced machine tool structure, the table is

selected to be fixed, the gantry frame does front and rear

(X-direction) movement on the slide, the front milling power head

does left and right (Y-direction) movement along the beam, and the

frontmillingpowerhead ram does up and down (Z) movement along the

slideThe rear two heavy-dutymilling headsmove left and right

(Y1,Y2) along the beam. Using finite element analysis, the static

and dynamic performance of the machine tool is effectively

predicted and optimized, so that the performance of the machine

tool is effectively guaranteed, with a highperformance-priceratio,

the machine tool can completeplateboring,milling, drilling and

tapping,chamferingand other processes. This machine tool is a new

type of high-efficiency heavy-duty processing equipment

independently developed by our company. The equipment has good

system rigidity and high precision, high life, high reliability,

high positioning accuracy, stable operation and low energy

consumption, which can meet the needs of efficient production of

enterprises. Itsfeatures are different fromothergeneral-purpose

machine tools,focusing on heavy cutting and

high-speedcuttingfunctions. Widelyused in steel structure, bridge,

pressure vessel, chemical environmental protection, engineering

machinery, ships and other industries. The processing process is

numerically controlled, easy to operate, and can realize automated,

high-precision, multi-variety, mass production. 2. The main

technical parameters:Effective machining workpiece size (length ×

width).12000×3000mmTable area (length × width)12500×3300mmX moves

the stroke15000mmFront milling power headY moves the stroke3000mmZ

movement stroke1000mmDistance from spindle end face to work

table100-1100mmSpindle taper holeBT50Spindle speed30-1800r/minMain

motor power30KWSpindle rated torque1050NmFeed speed (X, Y,

Z)5-2500mm/minFast movement speed (X, Y,

Z).8000/8000/4000mm/minX/Y/Z motor power3.5KW/4.4KW/7.5KWRear

heavy-duty milling headCutterhead formFormed cutterheadGroove

formY,U,V,XWorkpiece materialCarbon steel, low alloy steelWorkpiece

length3000-12000mmWorkpiece width1600-3000mmWorkpiece

thickness8-60mmUnilateral margin3-5mmMaximum spacing in the Y

direction3500mmMain motor power2×30KWSpindle speed200r/minMachine

loading5T/Positioning accuracy ISO±0.05/1000mmRepeatability

ISO±0.02mmControl systemFAGOR8055i3. Configuration of main

purchased parts:1. Control system: (Spanish FAGOR

FAGOR8055i)2. X-axis feed servo drive and motor: (Spanish)3.

Y, Z axis feed servo drive and motor: (Yaskawa, Japan)4. Rack:

(Taiwan YYC)5. Precision planetary reducer: (Taiwan Liming)6.

Precision spindle: (Taiwan Jianchun)7. Lead screw: (Taiwan

HIWIN/South technology)8. Linear rolling guide rail (Taiwan

HIWIN/South technology)9. Lubrication system: (American

Bechil)10, milling spindle gearbox (Taiwan GTP)11. Chip

conveyor (Cangzhou, Hebei)12. Main electrical components:

(imported)Note: If the supplier of the purchased parts fails to

deliver in time within the delivery period, the purchased parts can

be replaced by the same brand!4. The main components of the machine

toolThe main functional parts and key parts of the machine tool

have high quality, and imported or famous brand supporting products

are adopted. Its structure consists of bed, table, gantry beam,

slide, front ram milling power head, rear heavy duty milling head,

chip removal system , cooling and guarding, lubrication systems,

balancing systems, numerical control systems, electrical systems

and other main components. 4.1.Bed, workbench, gantry beamMachine

tool bed, gantrybeam, worktable,etc. are all welded structural

parts, which

Related products about CNC Gantry Boring Milling Machine Tool

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup