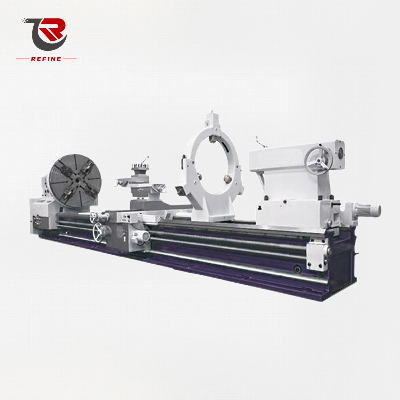

PRODUCTION DESCRIPTIONThese lathes can perform to turn end-faces,

cylindrical surfaces and internal holes of various parts as well

metric, inch, modules and pitch threads. The slides can be operated

individually by power for cutting taper surface. Long taper surface

can be turned automatically through the compound movement combining

longitudinal feed with the top slide feed; moreover, the machines

may be used for drilling, boring and trepanning.They are

characteristics of power, high spindle speed, highly rigidity. The

various ferrous and non-ferrous metals parts may be turned through

the heavy cutting by carbon alloy tools.The machine is available

for turning cylinder and cones, and do the works of end turning,

grooving, drilling , boring and trepanning, and also can cut all

kinds of inside and outside metric threads, inch threads, module

threads, etc.The machine is characterized by compact structure,

convenient operation, low noise and high efficiency, and is also

provided a complete set of accessories. This machine is especially

suitable for various machine industry, such as machine building

industry, light-textile industry, petrochemical industry, calve

industry, roll industry and so on.MACHINE PICTURES

PARAMETERS ITEMCT61100CT61125Max. swing diameter over

bed1000mm1250Max. swing diameter over carriage630mm880Max.

workpiece weight between

center1000/1500/2000/3000/5000/6000/8000mmSpindle bore100mmTaper in

spindle nose1:20Number of spindle speedsForward 12Reverse 12Range

of spindle speeds6-272rpm4.25-192rpmRange of feed per spindle

revolution48 kindsLongitudinal 0.057-12.726mmCross

0.027-6.096mmRange of metric threads46 kinds 1-224mmRange of

whitworth threads46 kinds 28-1 t.p.iRange of module threads37 kinds

0.25-56mmWorkpiece held on the steady rest50-540mmChuck Diameter

1400mmTool shank section45*45mmCompound rest Travel300mmRapid

moving speed of tool postLongitudinal 3.8 m/minCross 1.9

m/minDiameter of center sleeve140mm160mmMax. Travel of Center

Sleeve230mm300mmTaper in center sleeve boreMorse No.6Main motor

power22kw22kwMax torque10kn.mMax. workpiece weight6TWidth of

guideway755mmNOITEM1Steady Rest 2Follow Rest 3Center 4Center

sleeve5Revolving center6Oil gun7Change-gears8WrenchesMACHINE

FEATURESHigh rigidity mechanical 4-station tool rest, with high

reliability and high repeatable positioning accuracy The bed

adopts integral casting forming, the bed guide adopts mountain and

plane guide layout, with large bearing section The sliding

plate box of the machine tool is provided with a fast moving

device, which can be moved to the desired position quickly in the

vertical and horizontal direction. Machine tool spindle adopts

mechanical friction disc clutch: by controlling the bar, the

spindle can change speed, stop and reverse direction without

changing the motor speed and stop the motor. PACKING &

SHIPPING WHY CHOOSE US /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about CT61125 Heavy Duty Universal Metal Lathe/Engine Lathe

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup