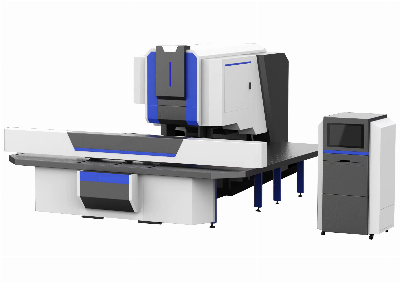

Product Description A flexible bending machine can quickly

locate Material location and then finish Four-sided bending, it is

fully automated during the bending process. The machine adopts

hydraulic and servo hybrid drive mods, This retains the ability of

hydraulically drive bending, and also incorporates the precise

control and stability of a servo drive. The combination of these

two gives the machine the advantages of easy adjustment, easy

maintenance, and low consumption. Stamping parametersBending

thickness of the iron plate0.4-1.5mmMaximum bending

size2.5m/1.4mMinimum bend

size300x300mm/270x270mmAccuracy±0.1mmMaximum

pressure63T/40TSize3500x3500x2400mm/2400x2400x2400mmWorkbench

maximum speed32m/minVoltage380/220vMaximum

power45kw/25kwweight14T/8T company

interduction Foshan ACU Machinery Equipment Co. ,Ltd. was

established in 2007 and is a physical equipment manufacturer that

integrates research and development, processing, manufacturing, and

sales. The company has a long history of operation and strong

strength. Through long-term research and development work, our

company has accumulated rich technical strength and valuable

experience. The developed and produced cold bending equipment has

the advantages of fast running speed, high stability, stable

operation, high yield, convenient operation, and low power

consumption, and is deeply welcomed by the majority of users. Its

products are widely applicable to the steel structure industry,

vehicle industry, door and window industry, home appliance

industry, elevator industry, and cooling tower industry, covering

all sheet metal industries.The company has more than technical

personnel of all kinds, and owns 15 national certified patent

technologies. It provides customers with professional design and

engineering cost analysis of cold-formed steel products, roll

design, calculation, molding process simulation, customized various

precision rolls, various coldformed steel equipment, and a full set

of Garage door equipment in cooperation with software equipment.

The company has advanced and professional production equipment:

machining centers, CNC lathes, milling machines, internal and

external grinding machines, etc. We have a rigorous quality

management system and advanced inspection and measurement equipment

to meet the quality of high-precision product production and

processing, thus meeting industry standards.The company adheres to

the principles of excellence and quality assurance, striving to

achieve the best mechanical quality. With the service tenet of

sincere customer service, we provide high-quality integrated

services to global customers. COMPANY CULTURE THE UNIQUE

HUMAN CARE AND PROFESSION PASSIONATE SALES SERVICE SYSTEMThe first

step in winning customer satisfaction is to understand customer

needs. Therefore, when we undertake new tasks, we must first listen

to the requirements of customers completely and accurately. Regular

training and innovative technical knowledge of service personnel

provide a strong guarantee for tailor-made products and

market-oriented solutions. WORKSHOP CERTIFICATE

OF HONOR CUSTOMER STORIES exhibition

FAQQ1. Production cycle of the machineA1:Our machine

production cycle is determined by the size of the machine

customized by the customer. Machines with less than 15 forming

wheels are small machines, and the production cycle is about 40-50

days. Within 25 groups are medium-sized machines, and the

production cycle is about 50-60 days. More than 30 sets of forming

wheels are large machines, and the production week is about 70-80

days. The fully automatic production line may be equipped with

hydraulic abrasive punching, CNC punching machines, CNC bending

machines welding machines, and other machines, so the production

cycle is about 90 days. (The time count starts when the contract

takes effect)Q2. Our payment ratio:A2:40% advance payment is

required before starting the manufacturing machine, and the

remaining 60% is required to be paid before shipment after

manufacturing is completed.Q3.Terms of Trade.A3:We are factory

direct sales, so we use FOB (if you need other terms, quote

according to the actual situation)Q4.Warranty period and

after-sales serviceA4:We provide a one-year warranty period. During

the warranty period, if the machine is not artificially damaged

(except for wearing parts), we will provide free maintenance

services, but visas, air tickets, board, and lodging must be

provided by the buyer. After the warranty period, we provide

lifetime service for the machine, but buyers need to provide basic

labor costs and labor travel expenses, the cost of replacement

parts is an extra count. In addition, we also provide remote

assistance to solve customer machine problems through video

conferencing.Q5.Machine efficiencyA5:Our machines are customized

according to customer requirements, and non-standard automated

production lines can meet customer requirements for

efficiency.Q6.Technical supportA6: Customized solut

Related products about High Progress Fast Suction Cupping or Pressing CNC Flexi Bending Machine Center with 1.4m-3.2m Workbench

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup