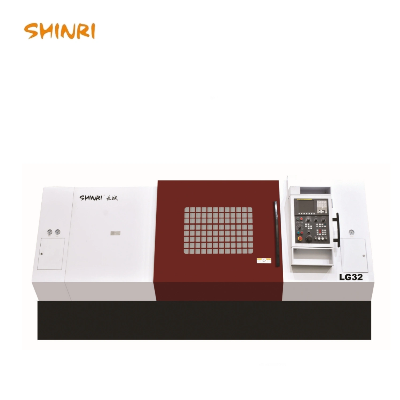

Product Description1.LS series CNC lathe are high accuracy, high

speed and high efficiency processing equipment from our

company.2.The machine tilt 45°horizontally, has the advantage of

compact structure, rational layout, well chip removal performance,

operation and pleasant and so on.3.High precision ball linear guide

pair is configured vertically and laterally, result in high

rigidity and good dynamic performance.4.The whole machine adopts

modular design and can meet the different functions and

configuration requirements of different customers.5.Well-designing

water tank and high lift centrifugal pump is adopted to realize

strong cooling for parts and chip removal

effect. Product

ParametersItemSpecificationUnitLG16ALG20ALG32LG40LG63Machining

capacityMax. swing over bedmmΦ400Φ500Φ630Φ670/Φ630Φ800/Φ760Max.

swing diameter over saddlemmΦ280Φ300Φ420Φ460Φ640Max. turning

diametermmΦ360Φ400Φ600Φ600Φ800Max. turning

lengthmm500400/650/1000750/1200/18001500/25001500/3000TravelMax.

travel X axismm195210+30310+30350460Max. travel Z

axismm590500/750/1100850/1300/19001710/25801740/3150SpindleSpindle

speedr/min50003500250020001800Centering journal taper of

spindle 14° 15″14° 15″14° 15″14° 15″14° 15″Tapwe of hole in

spindle Morse6#Metric system 80Metric system 100Metric system

120Metric system 120Spindle hole diametermmΦ55Φ65Φ85Φ100Φ110Front

axis dimension of spindlemmΦ90Φ110Φ140Φ170Φ170Distance from spindle

center to bed surfacemm230300360360455Distance from spindle center

to the groundmm95095010501060/11501200TailstockMax. travel of

tailstock quillmm80100140180220Diameter of tailstock

quillmmΦ85Φ100Φ140ΦΦ180Taper of hole in

mandrelMorseMorse3#Morse4#Morse5#Morse5#Morse6#ChuckHydraulic chuck

diameter 8″8″12″15″18″Feed rateRapid rate

(X/Z)m/min16/2018/2012/169/1310/10Feed rate (X/Z)mm/min0.001-10000/

0.001-120000.001-12000/ 0.001-160000.001-12000/

0.001-160000.001-12000/ 0.001-160000.001-12000/ 0.001-16000Control

systemCNC system GSKFANUC 0I-TFFANUC 0I-TFFANUC 0I-TFFANUC

0I-TFPower of spindle motorkW5.5/7.511/1518.5/2222/3022/30Servo

motor of X axisNm68122222Servo motor of A axisNm1012223030Tool

magazineTurret

type ElectricElectricElectricHydraulicHydraulicTool

stationstools812121212OD shank sizemm25×2525×2532×2532×2532×32Max.

diameter of boring barmmΦ40Φ40Φ50Φ60Φ80Machine

weightt2.64.8/5.3/5.88/9/10.512.6/14.814.5/20.5Company

ProfileSHINRI CNC Machinery Group is consisted of Jiangsu Shinri

Heavy lndustry Science &Technology Co., Ltd, Jiangsu Shinri

Gear Systems Co., Ltd Ningxia Shinri Changcheng Machinery Co., Ltd,

Ningxia Shinri Changcheng Casting Company Co., Ltd. Lt is

subordinate to the New United Group. Shinri products covered three

time-honored brands, respectively Shinri, Changcheng and Duoleng

and 12 different products series. So far Shinri becomes one of the

biggest machine tool manufacturers covering nearly alltypes of

machines in China.By embracing new, high and outstanding

technology, Shinri opens his hands to escalate his customers from

their traditional applications and gives optimized solutions. The

two R&D centers and manufactory bases, in Changzhou and

Yinchuan, have totalarea of premises of 700 thousands m and 300

thousands m modernized plants. We introduced a good number of high

precision mother machines from world first class makers and the

yearly machine production reaches to 3500 pieces or more. In

Yinchuan city, by invested 600 mllion RMB, the first phase of

construction of foundry plant has established with yearly capacity

40 thousand tons With strong financial, intelligent and technical

supports, the company is gigantic in R&D and manufactory.Its

products list covers VMC, HMC, CNC lathe, gantry boring

milling/machining center/5 faces/5-axis synchronous, floor type

boring miino/machining center, end facing & centering machine,

drilling machine, FMC, FMS, Railway gear box, Wind power gear box

and industrial gear box etc. The products are broadly applicable to

aerospace, automobile, shipbuilding, electronic appliance,

new energies sources, railway traffic, engineering mechanic, petro

chemistry, die tooling and vocational education...etc.As a national

enterprise endowed with the mission of rejuvenating Chinese

traditional industry, Shinri will follow the concept ofputing

people first, making innovations & building a future of excellence.

Work under the guiding principle of providing the highquality

products & best service for customers in order to become the most

competifive CNC machine tool manufacturer & bestsolution provider

at home & abroad./* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about High Performance and High Stability Full Functional CNC Lathe Turning Center Slant Bed Lathe High Accuracy Turning Machine LG32

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup