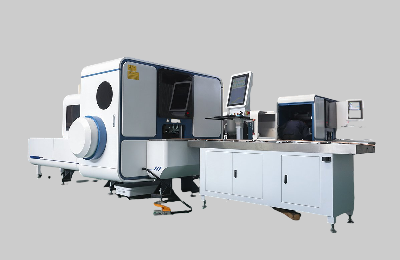

Product DescriptionMain Functions and Features:EMAC-BP

series CNC busbar punching & shearing machine is the

computer-controlled equipment of high efficiency and high

precision, specially used for busbar processing; Dies of punching,

shearing are placed together in the storeroom of dies; It is

capable of executing punching(round, oblong and other holes),

shearing, slotting, round cornering and other processes; Automatic

clamp switching can be achieved without manual intervention for

longer busbars. Finished work pieces will be sent out through the

conveyor. Such machine series can be used in combination with the

CNC busbar bending machine to form an assembly line of busbar

processing. Our AdvantagesSmartbar 3D software--This is our

independent patent in busbar processing, which can realize 3D

automatic programming and dynamic simulation.Double

clamps--Comparing other single clamp, double clamps can make

processing more accurate and stable.Hydraulic system-- Piston pump

(rather than gear pump) has large drive power and realize high

efficiency.Main components--Imported, so the quality and service

life can be guaranteed.Product Parameters Technical

parameterDescriptionUnitParameterPress ForcePunching

UnitkN300Shearing UnitkN300X Max Speedm/min48X Max Strokemm1000Y

Max Strokemm530Z Max Strokemm350Stroke of Hit Cylindermm45Max hit

speedHPM60ToolPunching Mouldset4Shearing Mouldset1Control

Axis 3Hole Pitch Accuracymm/m±0.20Max hole punch sizemmΦ32(

Press

Related products about Beiene Intelligent CNC Hydraulic Busbar Punching Shearing Processing Machine for Metal

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup