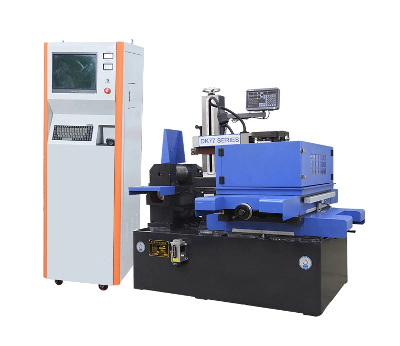

The WEDM is composed of main machine, electrical control system,

software and cooling filter system. The main machine is mainly

composed of fuselage, column, wire frame, workbench, etc. the

structure of the machine tool is compact and the design is

reasonable. It has five axes of X, y, u, V and Z, among which the

four axes of X, y, u and V are linked and driven by step without

resistance and constant current. The vertical cabinet dqe-ds-03

(full step type) of the electrical cabinet is made of cold-rolled

steel plate, with electrostatic spray molding. The interior is

equipped with computer and control software, high-frequency control

module, driver, frequency converter, fan, etc. The cooling system

includes water tank, cooling pump and filter screen.Long term

normal working conditions of the machine:

Workingenvironmenttemperature5~40ºCrelative

humidity≤85%Workingtemperatureofcooling water≤30ºCPower

Supply380V±5%, can make as 415V;50Hz±1Hz;Three phase alternating current2.technical

requirementS/Nprojectparameter1modelDK771002Electrical cabinet

formVertical cabinet (full step type)3GuideSteel rail4Lead screw

formBall screw5Xyuv motion motor formReactive stepping

motor6Working mode of wire conveying motorFrequency converter speed

regulation1~12m/s7Machine tool protectionEnvironmental protection

cover8Resolution of motion axis0.001mm9Table size1600*115010X, y

axis stroke1000X1200mm11U, V axis

travel±35×±35mm,(±60×±60m)12Machining taper / machining

thickness±6°(±15°)/80mm13Maximum straight cutting

thickness1000mm(Z-axis manual lifting)14control mode4 axis

linkage15Maximum load capacity1100kg16Maximum processing

current8A17Maximum machiningefficiencyCr12,H=60mm≥180

mm²/m,Aluminum cutting≥220 mm²/m18Surface roughness(Straight line

cutting,H≤40mm)Ra≤1.6μm19Cutting accuracyCr12,H=40mm≤0.01mm20Radial

runout of wire storage cylinder≤0.02mm21Molybdenum wire diameter

range0.12~0.22mm22Wire storage capacity of wire

storagecylinder250m23Loss of molybdenum

wireCr12,H=40mm≤0.02mm24Cutting power supplyHigh frequency power

supply system withoutresistance25operating systemWindows

XP26Control systemAUTOCUT27communication

interfaceLAN,RS232,USB28Operation functionDrawing or CAD (DXF)

drawing import29Volume of working tank55L30Working fluid filtration

modeFilter screen filtration31Weight of whole

machine6000kg32Overall dimension of main

engine2500x2300x2500mm33Cabinet size730×630×1820mm34Rated power of

electric appliance≤ 2.7 kW 3.List of attached

accessories S/NProduct nameSpecificationsFree

delivery1scissors312HexagonalwrenchM4-M10(5)13Stiff

hands14-1714WoodenscrewdriverOne type, cross type25Oil gunMetal

shell16Molybdenumwire calibratorH80mm17Top wire

wheel 18Working fluidWater working fluid, Jiarun

jr3a19Electrode wireRecommended0.18mmmolybdenum wire500m10Guide

wheelDia.49.5mm211Bearing625ZZ812Conductive block12mm×12mm213ReversingswitchNPN

LJ186A3-8-Z BX214Silkconveyorbelt1101/* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about High Quality High Speed Wire Cut Wedm Machine for Metal Dk77100

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup