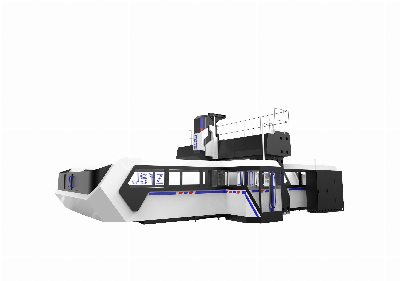

SKZX5050 gantry drilling and machining center is a large-scale

workbench mobile fixed column and fixed beam high-speed drilling

and milling gantry machining center independently developed by our

company for wind power generation, slewing bearing, chemical

equipment and other industries. Its characteristics mainly reflect

high-speed drilling, high-speed cutting, to achieve internal and

external cooling functions, in recent years this series of products

have been widely used by

customers. This product has a wide

range of applications and strong processing capacity. Mainly used

for all kinds of extra-large bearing rings inner and outer ring

hole rough finishing, machine tools can realize the box, shell,

bearing and other parts of the bore and hole system, contour

complex shape, surface and various types of plane boring, milling,

drilling and other processes, with expansion, hinge, countersinking

plane, tapping, milling thread and straight, arc interpolation and

other functions. The machining center

adopts the international advanced machine tool structure, applies

finite element analysis, and effectively predicts and optimizes the

static and dynamic performance of the machine tool, so that the

performance of the machine tool is effectively guaranteed, and has

a high performance-price ratio. CNC system, hydraulic system, feed

system, speed regulation system, etc. all adopt domestic leading,

international advanced mature technology, high precision of

executive components, good reliability, excellent dynamic

quality. First, the basic performance and characteristics of

the machine toolSKZX5050 gantry machining center is a large-scale

workbench mobile fixed column fixed beam high-speed drilling and

milling gantry machining center independently developed by our

company for wind power generation, slewing bearing, chemical

equipment and other industries. Its characteristics mainly reflect

high-speed drilling, high-speed cutting, to achieve internal and

external cooling functions, in recent years this series of products

have been widely used by customers. This product

has a wide range of applications and strong processing capacity.

Mainly used in all kinds of extra-large bearing ring inner and

outer ring hole rough finishing, machine tools can realize the box,

shell, bearing and other parts of the bore and hole system, contour

complex shape, surface and various planes of boring, milling,

drilling and other processes, with expansion, hinge, countersinking

plane, tapping, milling thread and straight, arc interpolation and

other functions. The machining center adopts the

international advanced machine tool structure, applies finite

element analysis, and effectively predicts and optimizes the static

and dynamic performance of the machine tool, so that the

performance of the machine tool is effectively guaranteed, and has

a high performance-price ratio. CNC system, hydraulic system, feed

system, speed regulation system, etc. all adopt domestic leading

and international advanced mature technology, and the execution

components have high precision, good reliability and excellent

dynamic quality.Feature 1:The spindle box adopts asliding ram

structure, which can realize high-power heavy-duty cutting and

high-speed drilling functions, and the guide railis a

squarequenching-pastedsliding guide pair, with high rigidity, good

vibration absorption and high stability. TheY-axis slide seat

has a long length of inclusion for the ram guide, which keeps the

square ram cutting smoothly when extended machining. The ram guide

rail is ground by GermanWALDRICHguide rail grinding machine, with

high precision and good stability; German WALDRICHrail grinder

ramFeature 2:Self-developed programming software, CAD/CAMgraphics

can be automatically converted into processing program functions

when drilling, eliminatingthe cumbersome steps of manual

programming. Feature 3:This machine tool hasdrillingreal-time

torque detection function, can set and protect the tool torque,

when the tool wear cutting torque is greater than the set torque

value for tool lifting shutdown protection, to ensure that the tool

will not be damaged, greatly reduce the cost of tool use. Feature

4:This equipment adopts GermanSP laser geometric measuring

instrument from the guide rail installation, detects the

straightness and levelness of the guide rail, so that the machine

tool slides on the guide rail more smoothly and accurately, and

uses laser interferometer correction to accurately detect and

compensate for pitch error, backlash, positioning accuracy and

repeated positioning accuracy to ensure the dynamic, static

stability and processing accuracy of the machine. Feature 5:The use

of Taiwan Jianchun center effluent spindle, front four rear two

group bearings, so that the spindle has high precision, high load

and low temperature rise, with GermanSIEMENShigh-power servo

spindle motor, through TaiwanGTPtwo-speed gearbox automatic shift

transmission Passed to the p

Related products about Skzx-5050 Ganmen Drilling Center CNC Machine for Gantry Machining Center

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup