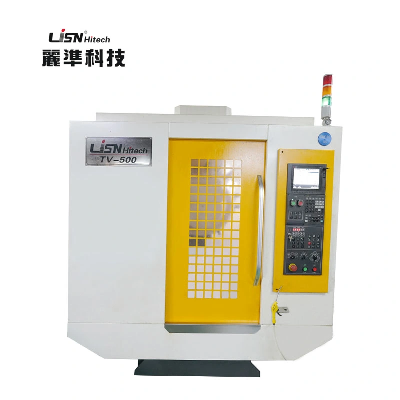

Product DescriptionThe 4 axis TV-500 is a high performance CNC

Drilling and Tapping Machine with high speed, high precision and

high rigidity characteristics. The fuselage and saddle of the

machine are reinforced by mountain shaped ribs to provide the best

rigidity to the machine. The contact length ratio between the

main shaft and the column is appropriate to provide stable support

for the main shaft. Independent cooling system is built in the

spindle head to stabilize the spindle continuously. The head

heat is in a reasonable range, which reduces the thermal extension

of the spindle and ensures the machining accuracy. it adopts a

super high performance servo motor which was imported from Japan

to provide stronger power when heavy cutting.The whole machine

adopts a positive displacement lubrication system and a de

pressurized oil pump, with stable pressure and flow, which

effectively transports the oil to each lubrication point and

provides uniform forced lubrication for each slide surface, so as

to ensure the accuracy and service life of the machine

tool. It adopts Okada or Desu disc manipulator tool

magazines, which are installed on the side of the column. It has

the characteristics of fast changing speed, accurate tool changing,

high efficiency and long service life. Main FeaturesHigh

rigidity of the machineHigh speed and precision spindleMaximum

cutting feed speed: 1-20000RPMExcellet worktable size:

650mm*420mmMaximum load capability: 200kgMitsubishi M80

SystemDetailed Photos Product

ParametersITEMMODELSTV500WORKTABLE

(WIDTH*LENGTH) mm650*420DISTANCE BETWEEN T SLOTSmm14*3*100MAX

LOAD BEARING OF WORKTABLEkg200X/Y/Z AXIS

TRAVELmm510/400/350 DISTANCE FROM SPINDLE NOSE

TOWORKBENCHmm130-480SPINDLE HOLE TAPER BT30SPINDLE SPEED

RANGEr/min12000TRANSMISSION OF SPINDLE

BOXBELT/DIRECTOptionalSPINDLE MOTOR POWERkW3.7/5.5( Mitsubishi)

/5.5/7.5(Fanuc)X/Y/Z RAPID FEED SPEEDm/min48/48/60(60/60/60)MAX

CUTTING FEED SPEEDmm/min1-20000TOOLS MAGAZINE

CAPACITYpcs14()16/18/21()FULL TOOLS MAX TOOL

DIAMETERmm∅80/∅120MAX.TOOLS ALLOWABLE WEIGHTkg3.5MAX.TOOLS

ALLOWABLE LENGTHmm200TOOL CHANGE TIMEsec1.8COOLING PUMP FLOW

RATEL/min200X/Y/Z POSITION ACCURACYmm±0.005X/Y/Z RE-POSITION

ACCURACYmm±0.003 CONTROL SYSTEM Mitsubishi, Siemens,

FanucSPINDLE BRAND ROYAL, Taida, VYU CHENGBALLSCREW

BRAND Taiwan, Hiwin, PMITOOL MAGAZINE BRAND TaiwanHEAT

EXCHANGER BRAND RucolMACHINE DIMENSIONmm1540*270*2500MACHINE

WEIGHTkg1500AIR PRESSUREkg/cm27 Standard Configuration for TV

Series Full Cover shield / Self-lubrication system / Working

lights / Warning lights / Working condition warning lights /

Self-powered electrical shutoff system / Clean air gun/ Water Tank

/ Transformer / Spindle air curtain and dust control system /

Rigid Tapping / Worktable cleaning water gunOptional

Configuration TV SeriesNC rotary table (4 Axis) / CTS /

Tool detection system / Automatic tool length measurement

and damage detection / 3 Axis Linear Scale / Disc type

oil-water separator / Crawler chips remover / Direct

connection spindle / Spindle oil cooler Company

ProfileLizhun Machinery Co., Ltd. is a company focused on

innovation, development and production of CNC machining centers and

CNC lathes. Adhering to the spirit of innovation and excellence,

the company has provided many famous enterprises at home and abroad

with extremely superior machines in performance, precision and

quality. In the future, Lizhun will continue to maintain the

spirit of innovation and excellence to provide strong and lasting

support for the processing industry, and provide excellent

processing machines for 5G, aviation, automobile and other

industries. Lizhun Machinery Co., Ltd. is located in

Dongguan, Guangdong province. The product exhibition hall is

located in Songshan Lake, Dongguan City, with beautiful scenery and

elegant working environment. The factory is located in Dalingshan,

with complete facilities and experienced staff. The staff has many

years of experience in innovation, development, assembly and

production, which ensures that each machine has extremely

outstanding quality and performance when it leaves the

factory.The factory covers a large area and has multiple production

lines to ensure production capacity and supply capacity. Excellent

capacity and supply capacity can ensure that customers can receive

the machine within the agreed time which can avoid a series of

problems caused by insufficient capacity. FAQ1. Is it all

right to make customer's own brand name?A: yes. we are available

with OEM 2. Are you a manufactuer or trading company?A:We are

the manufacturer 3. Can you do the design for us?A: yes. if

you want a different control system design or higher column , we

are available. 4 . What is your terms of delivery?A: FOB

shenzhen. 5. What's your payment term?A: T/T OR L/C at

sight./* March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about TV500 4 Axis Drilling and Tapping CNC Machining Center CNC Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup