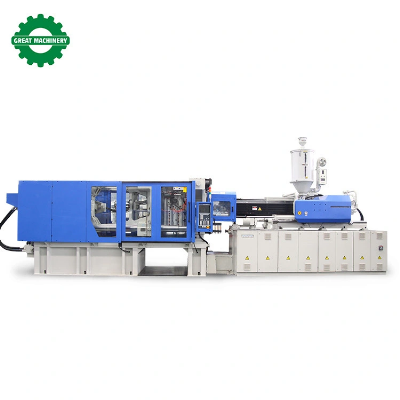

Horizontal Automatic Servo Energy Saving Plastic PE PP

Injection/Moulding Molding Machine Our new type dream series

Plastic molding machine price is very good, it's energy saving

effect reaches to 50%~70%, especially more for products need long

cycle time. It was promote many technical points as following:

CLAMPING UNIT: -T-slot board easy for making and logistic

management -A big row angular, international popular design,

adopted, (combined with technology Netsta and Demag), small

clamping force required, clamping and opening run fast and smoothly

-All plates through UG finite element analysis, receiving a force

evenly INJECTION UNIT: -Multi-specification of injection

equivalent, modularization design for meeting the requests from

customer. -Twin cylinder nozzle movement as standard, connection

between nozzle and mold is stable to ensure no leaking of

materials. -More detailed division and specialization of design for

screw and barrel according to different plastic materials to ensure

the injection precision as well as processing requests of various

materials. Electric Control -4 transducers as standard make

machines more easy and convenient to operate. -Except for

standardization, the design of electrical boxes explored the

features with intense current, light current and servo driver to be

separated, signal interference reduced to the lowest degree and big

area to promote heat loss as well as repair and maintenance

conveniently in terms of effective fault reduction. Product

Parameters UnitD400SITEMSABCINECTION UNITScrew

Diametermm65 70 75 Screw L/D RatioL/D23.7 22.0 20.5 Shot

Size(Theoretical)cm31161 1347 1546 Injection Weightg1057 1226 1407

Injection PressureMPa221.8 191.3 166.6 Injection Rate into Air

cm3/s269.8 307.3 312.9 356.4 359.2409.1 Injection

Strokemm350 Injection Speedcm/s8.1/9.3Screw Speedrpm166

/189CLAMPING UNITClamping ForceKN4000 Clamping Strokemm750

Space Between Tie Barmm730*730Max. Mold Heightmm750 Min. Mold

Heightmm280 Eject Strokemm200Eject ForceKN124No. Of Ejector

Pinspiece13 OTHERSMax. Pump PressureMPa17.5 Pump Motor PowerKW33.5

37.0 Heater PowerKW24.2Hopper CapacityKg50 Oil Tank

CapacityL800 WeightT14.4Product Description Our servo system

was the energy saving device that can save Min.50% electricity

power for larger models of injection molding machineOur Servo

injection molding machine system including:1.Servo Motor:

PHASE from Italy2. Servo controller driver: Inovance from China3.

Gear Pump: ECKERLE from Germany4. Computer controller: Techmation

from TaiwanCompany Profile Packaging & Shipping /*

March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Horizontal Automatic Servo Energy Saving Plastic PE PP Injection/Moulding Molding Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup