Technical data for series of STIBM95STechnical

Parameters Preform systemUnitSTIBM95S Screw

diametermm65 Screw L/D L/D23:1 Shot

volumecm3660 Injection weight(HDPE)g625 Max.Screw

speedrpm10-235 Heating capacityKW12.6 No.of heating

zoneQty3+N Clamping system Clamping force of

preformKN1008 Clamping force of blowingKN221 Opening

stroke of mold plantenmm160 Lifting H of rotary

tablemm80 Max.Platen size(L×W)mm900×480 Min.mold

thickness(H)mm280 Heating capacity of mouldKW8 Stripping

system Stripping strokemm260 Dry

cyclesec3 Driving system Motor

powerKW26+26+3 Hydraulic pressureMpa14 Product

range Suitable bottle rangeml5-800 MAX.bottle

heightmm≤220 Max.Dia.of

bottlemm≤100 Other Min.air

pressureMpa1 Discharge rate of compressed

airm3/mm≥1 Water flowagem3/h6()Total rated power with mold

heatingKW75.6 Dimension(L×W×H)M5.0×2.0×2.6 Net

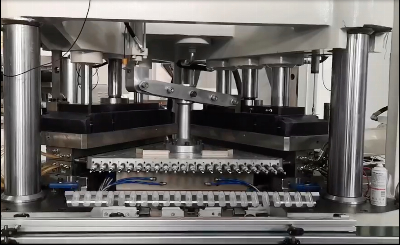

weinghtton12STIBM95S Injection blow molding machine main parts

configuration NameBrand1Electro-Hydraulic system++INOVANCE

controller+motor+SUMITOMO pump:++Or TECHMATION

controller+PHASE motor+ECKERLE pump 2Hydraulic

motor INTERMOT OR STF3 Hydraulic

valveYUKEN4 Seal KitCOG,DINGZING,HALLITE5AccumulatorOLAER6Oil

cooler DELTA7High-pressure hoseEATON orCONTITEC

orPARKER8Air ValveSMCFESTO9Pneumatic connectorCAMOZZI10Control

systemPLC+ OMRON+MCSG11A.C.

Contactor SCHEIDER12 Relay, OMRON or SCHEIDER13Promixity

switch OMRON14Linear Scale GERFAN/* March 10, 2023

17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about 22 Cavity Injection Blow Moulding Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup