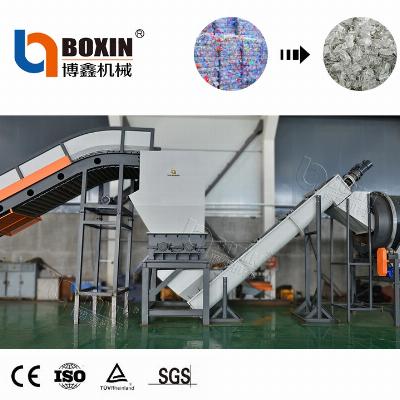

Pet Material Waste crushing washing pet line with Pressure Sensors

crushing washing pet lineProduct Description1. This PET hot washing

plant mainly used for dealing with waste PET bottles, barrels

etc.2. To separate dirty PET bottles to flakes with label, cap,

oil, garbage etc.3. This PET Bottle Washing Line is composed of

sorting, crushing, cold & hot washing , dewatering, drying ,

packing etc.4. Easy to operate, Full automatic.5. This pet

bottle washing line can be displayed "L" or "U" shape according to

clients' workshop.6. Reasonable process design and good

cleaning effect .Final PET flakes products have good quality.When

processPET bottle, final products humidity below 1%,

impurities100ppm,PVC label content 100ppm .The whole line capacity

is between 300kg/h-5000kg/hour. High production capacity (more

than 30% higher than the same equipment in the same industry), low

energy consumption (water, electricity, gas, chemical cleaning

agent consumption is 20% lower)The material which contact with

water use SUS304 stainless steel, thickness more than 3mm, to

ensure long lift

time. ModelBXA-500BXA-1000BXA-2000BXA-3000BXA-5000Output(KG/H)5001000200030005000Installed

power(KW)160-180210-260400-460600-670920-1200Water

consumption(T/H)2-33-56-810-1212-15Labor

requirements2-34-55-66-88-10Factory

area(L*W*H)70*5*585*5*5100*8*6120*6*6135*8*701 Conveying and

De-baling SystemThe adjustable speed metal chain conveyor greatly

improves the efficiency and more durable.The De-baler machine

adopts the special structure design of angle 2-axis unpacking and

2-axis breaking, which can fully dissolve the bottle bricks to

ensure the subsequent conveying process, and at the same time

reduce the energy consumption to the greatest extent.02 Label

Removing SystemMainly used to peel off the label paper on the PET

surface;Ensure the integrity of the bottle and neck, reduce the

loss of high-quality bottle finish.03 Manual Sorting SystemFinal

classification and sorting of bottles before crushing;The sorting

system is a necessary way to ensure the quality of the foreign

matter remaining in each unit of the previous section.04 Crushing

SystemAccording to different output, choose different types of

crusher;The main shaft and box of the crusher are made of

wear-resistant materials, which are safer and more durable.05 high

Speed Fiction Washing SystemAdd high-speed friction washing machine

to remove impurities more effectively and achieve ideal cleaning

effect.06 Hot Washing SystemHot washing effectively removes

residual glue, oil stains and some fine impurities on the surface

of the bottle.07 Dewatering MachineThe moisture content of the

final material plays a vital role in the next process;It can

be equipped with corresponding centrifugal dehydration and hot air

drying system according to your production requirements of moisture

content .What We will Do?After getting waste plastic raw

material, BOXIN Technicians will study and analyze the main

contaminants to provide a proper solution to remove most of the

impurities by mechanical, chemical, physical and other

principles.Main process of the whole project included pretreatment

of raw material → sorting → pre-washing → crushing →

hot washing → cold washing → drying → package → granulation.

BOXIN Machinery is a creative company, focusing on the

technology R&D of plastic recycling, and providing the

equipment and solutions for plastic washing, recycling and

granulating. BOXIN Machinery plastic recycling technology mainly

applied in the field of waste plastic regrinding, washing and

regranuling. Thanks to the R&D ability and well-understanding

industries experience, BOXIN Machinery can provide the customized

plastics recycling solutions to customers. Typical productions

Machinery can provide are: plastic washing line for PET bottles, PP

PE film bags, HDPE Bottles, Plastic pelletizing recycling line

for clean PP PE material, plastic shredder and crushers etc.

Advantage of Machinery: Specialized R&D team involved in

plastics recycling industries more than 18 years; Ability to

provide the customized plastic recycling solutions; Complete sales

system covering the pre-sale, sales and after sales; Professional

engineers will perform debugging and technical guidance.

/* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Pet Bottle Recycling Machine Plastic Recycling Plant Waste Plastic Recycle Machine Line

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup