High Quality PA Therma Break Profile Macking Machine Product

Description of High Quality PA Therma Break Profile Macking

MachineThe utility model mainly uses the special screw to make the

polyamide nylon 66 and the glass fiber obtain good plasticization,

and the extrusion die/tool extruded into a thermal insulating

strip, which is widely applied to the doors, windows and curtain

wall aluminum sheets through the different sections of the

die.PA66+GF pellets after drying machine into the hopper into the

barrel, screw and pellets contact with the rotation of the screw

forced to promote the spiral groove die direction. Because the

screw barrel gap is small, the granular material is hot body under

great pressure in the forward process; the temperature of the

electric heating ring body is plasticizing nylon thermosol. Nylon

plastic and plastic compression heating hot melt by extrusion

molding, after traction, cutting or rolling process and become

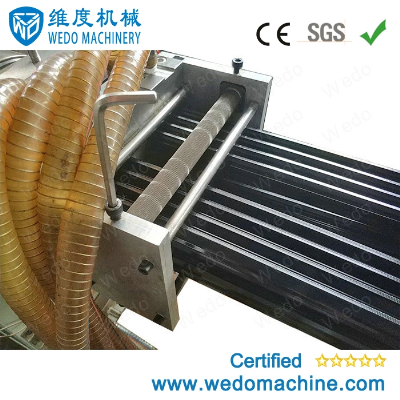

adiabatic adhesive tape products.Photos of High Quality PA

Therma Break Profile Macking Machine over view of High

Quality PA Therma Break Profile Macking MachineMold tools

of High Quality PA Therma Break Profile Macking Machinemold

tools proudce of High Quality PA Therma Break Profile Macking

Machinethe mold tools of High Quality PA Therma Break Profile

Macking Machinethe thermal profile strip installed after High

Quality PA Therma Break Profile Macking MachineMaterial and the

product of High Quality PA Therma Break Profile Macking

MachineThe PA thermal break profile strip bars functionWhy use

polyamide strip as thermal barrier function?1. Because polyamide

strip including Polyamide and glass fiber, Its Strength can reach

requirement for aluminum profile window, door, curtain and walls.2.

Conductivity of polyamide strip is very low, prohibit hot air or

cold air transferred from outside to inside, energy saving

product."Wear a process" heat insulation material - the current

domestic thermal insulation strip is polyamide 66+GF25

(Polyamide66, commonly known as nylon 66+25% glass fiber)1 main

materials

PA66+GF2 density

(g/cm3)

1.33 tensile

strength

(N/mm2 = 110)4 elastic modulus (N/mm2)

9005 thermal conductivity (W/m2.k)

0.36 hot deformation temperature (ºC)

250 Application of polyamide strip:1. Used for thermal break

aluminum window, door, curtain and walls2. Many customer use

thermal break aluminum profile to do big air conditioner to keep

heat of cold air, then make use of energy saving High Quality

PA Therma Break Profile Macking Machine including:1, Raw

material loading device(automatic)2, Raw material drying device3,

Main thermal break strip extruder4, Polyamide strip moulds /

tools5, Multiple polyamide strip collector6, Control

cabinet Wedo Produce steps:Wedo have a fully step

for the PA66 GF25 Polyamide Nylon Strips Thermal Break Profile Bar

Extrusion Making Production machine producing before packing

and shipping, this ensure the plastic recycling machine will

delivery in good quality, and custerm will get good machine.Wedo

service:We do best service for you in PA66 GF25 Polyamide Nylon

Strips Thermal Break Profile Bar Extrusion Making Production

machineAny further about the High Quality PA Therma Break Profile

Macking Machine, please contact us timely we will give your

professional fully support./* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about High Quality PA Therma Break Profile Macking Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup