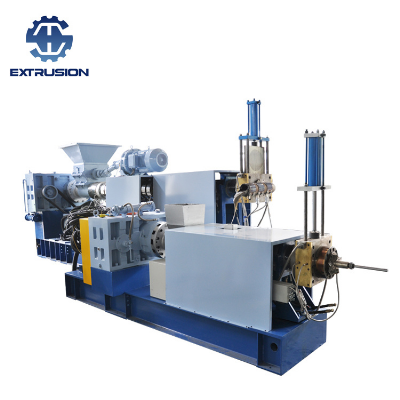

Introduction:Waste plastic granulator mainly for PP, PE plastic film (PP/PE film, PP/PE plastic bags, PE

plastic film mulching films shed, PP woven bag bag tons of cement bags, PP nonwoven) crushedto granulation , make plastic pellet full, even and without porosity, suitable for all kinds of waste plastic regeneration granulation recycling.For

waste pp/pe plastic film, plastic bottle and others, we strongly

suggest you our HMS series two stage single screw

extruder.Technical Data:ModeDiameter(mm)L/DMotor power(kw)Screen

ChangerCapacity(kg/h)SJ-10010020-3230-70Hydraulic120-200SJ-12012020-3237-45Hydraulic200-300SJ-15015020-3255-75Hydraulic250-350SJ-18018020-3275-90Hydraulic300-450SJ-20020020-32110-160Hydraulic500-800Raw

material: If your material are like these, and you do not want

to spend too much on the recycle machine. our HMS single screw two

stage extrder is your best choice!ApplicationThe new granules from

our machine can be used in manufacture machine parts, water pipes,

bags, buckets, toys and other living utensils.Our

advantages:non-stop screen changer die head: better for filter

impurities. It saves you huge cost on washing the waste

plastics.Auxiliary machines you may

need:The line with belt conveyer ,crusher ,extruder, auxiliary equipment. The line with characteristics of high output,low energy dissipation,labor-force saving,and high quality pellets,is an ideal equipment for film recycling and granulating line.Work

Line of the recycling granulating Machine :The first step: washing

and crushing lineThe second step: Granules pelletizing

lineFeatures of water cooling strand pelletizing systemWater cooling strand pelletizing system could be applied to most polymer materials processing and application, the entire system is simple and practical, more convenient operation and maintenance. Main components typically include: extrusion template, cooling water tank, drying machine, cooling granulator, vibrating screen and follow-up silo packing system.

Nanjing HaiSi Extrusion Equipment

Co., Ltd is a High-Tech company, which is composed of

well-experienced team in R&D, manufacturing technique, sales

service and basing on extruder industry for many years. Our company

is a professional manufacture of high quality pelletizing extruders

for coloring/ dyeing and master batch production, as well as

plastic modification and compounding, plastic recycling. Innovation

machines are built as per the concept of durability, high

efficiency and economical power consumption. /* March 10,

2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about PP PE Film Recycling Line Single Screw Extruder

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup