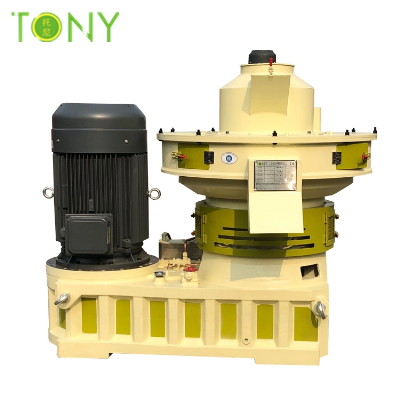

Sawdust Wood Pellet Mill /Rice Husk Pellet Press Machine with

Capacity 1.5-2 Ton Per hourCompany IntroductionTONY is a

professional manufacturer and exporter engaged in the research,

production, sale and service of Biomass wood pellet line, wood

pellet mill, grinding equipment, crushing equipment, drying

equipment, cooler and other screening, conveying equipment.Having

developed the pellet machines with reliable functions, reasonable

design, energy saving and high efficiency low consumption, our

vertical ring die pellet mill which use special gear transmission

has sold very well during home and aboard.We always supply the most

suitable machines for customers with excellent quality and

competitive price.Tony new bigger gear transmission wood pellet

machine is mainly used for medium and big process plant. The

pellet machine is a new generation of energy-saving green power

products, researched and developed by our researcher newly. The

pellet machine is mainly used to compress crushed wood, corn straw,

plant waste, bamboo powder, grass, straw, rice husk etc. into

pellets. The pellet machine adopts bipolar speed adjusting, and

have the characteristics of low power consumption, reasonable

structure, economic and durable.Raw material: wood, waste wood and

straws, etc. such as woodchips(palm, pine white pine, mahogany,

pinus sylvestris, rubber tree),bamboo shavings, rice hust, seeds

shells, peanut shells, halm, pennisetum, wheat straw, corn stalk,

cotton stalks, alfalfa grass,bagrass, palm fiber, waste paper,

non-physical materialSize:2-4mm (All the raw materials must be

crushed into sawdust before goingto wood pellet machine.If not, you

may need a wood chipper, wood crusher.)Moisture: Generally, 10-15%

is best for producing good quality wood pelletMain Features1)

Automatic lubrication system for the rollers and spindles which can

reach the machines run 20 hours without

resting.Hightempreture/pressure,and low temporeture/pressure

warning and automatic lubrication.-----Other suppliers did not have

this system,they have to lubricate each working time for about

8hours.2) Big gear Transmission for easy operation and lower

maintenance.Two big gears,each weight is more than

1.3ton.-----Other suppliers all use the reducer transmission,which

is easy to break,and higher maintenance.3) 4 rollers working,

increasing press rate and capacity.-----Other suppliers all use the

2 rollers.4) Double layers ring die type, longer working

lifetime.Customer Case: /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Sawdust Wood Pellet Mill /Rice Husk Pellet Press Machine with Capacity 1.5-2 Ton Per Hour

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup